Melamine formaldehyde resin preparation pdf

Polymer Dr. N. K. Patel EXPERIMENT: 5 PREPARATION OF MELAMINE FORMALDEHYDE RESIN Aim: To prepare melamine formaldehyde resin. Requirements: Melamine, formaline

The same procedure was used for the preparation of the melamine formaldehyde resin (MF) with a mixture of 33 g K 2 CO 3, 21 g melamine and 20 ml formaldehyde. The resultant solid resins were cured for a week at room temperature and then placed in a vacuum oven for 24 h at 75 °C to ensure complete dryness, then powdered.

3.3 Waste rubber powder preparation 25 3.4 Treatment of waste rubber powder 25 3.4.1 Treatment of waste rubber powder with 20% nitric acid 25-26 3.4.2 Treatment of waste rubber powder with 30% hydrogen peroxide 26 3.4.3 Treatment of waste rubber powder with acetone 26-27 3.5 Melamine urea formaldehyde based resin preparation 27 3.6 Optimization and formulation of melamine urea 27 …

–Formaldehyde –Melamine formaldehyde resin –Phenol-formaldehyde resins –Urea formaldehyde resin IHS Markit Formaldehyde & Resins. Title: IHS PDF Report Created Date: 9/29/2017 8:13:17 AM

Preparation of Nitrogen-Doped Carbon Nanotubes with Different Morphologies from Melamine-Formaldehyde Resin Yi Yao † ‡ , Bingqing Zhang § ∥ , Jingying Shi † § , and Qihua Yang * † † State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, Chinese Academy of Sciences , 457 Zhongshan Road, Dalian 116023, China

Melamine-formaldehyde resin, any of a class of synthetic resins obtained by chemical combination of melamine (a crystalline solid derived from urea) and formaldehyde (a highly reactive gas obtained from methane). A complex, interlinked polymer that cures to a clear, hard, chemically resistant resin

Polymers 2017, 9, 109 3 of 12 2.1.2. Samples for Melamine-Formaldehyde (MF) Reactions under Weak Acidic Conditions The pH of 16.22 g formaldehyde aqueous solution (37%) was pre …

Yan Jiang, Wanli Zhou, Mengjin Jiang, Pengqing Liu and Jianjun Xu, Flame retardant study of formalized polyvinyl alcohol fiber coated with melamine formaldehyde resins and the synergistic effect of copper ions, Polymer Degradation and Stability, 144, (331), (2017).

Melamine resin or melamine formaldehyde (also shortened to melamine) is a hard, thermosetting plastic material made from melamine and formaldehyde by polymerization. [1] In its butylated form, it is dissolved in n -butanol and xylene .

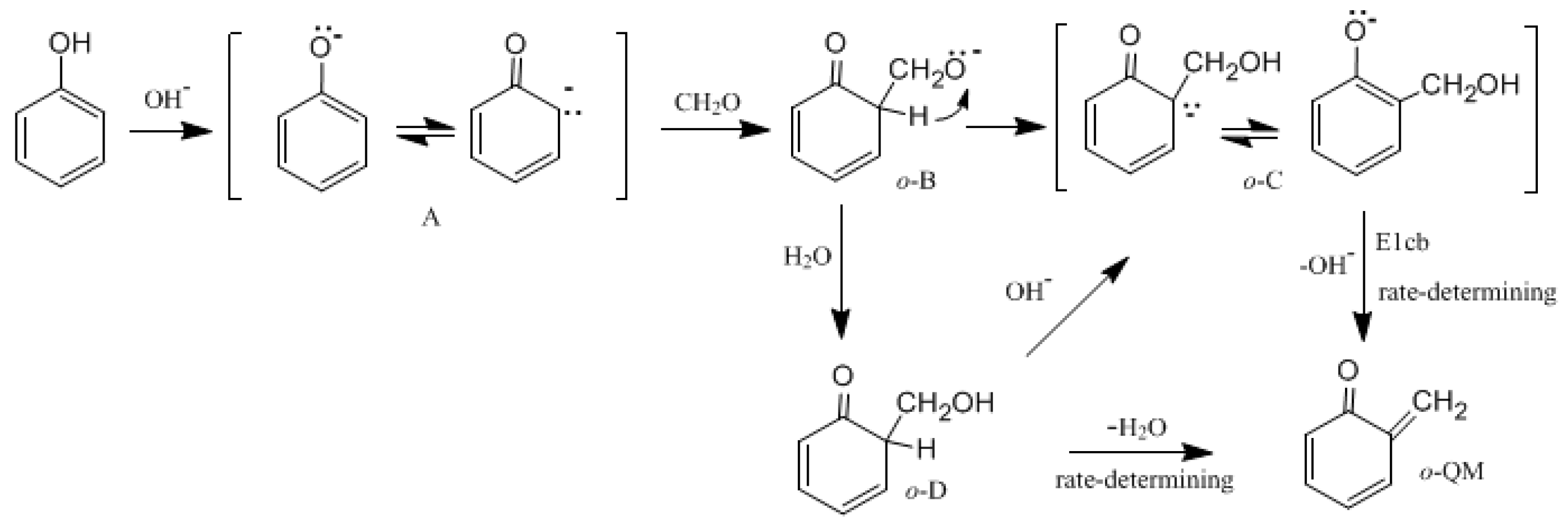

nitrogen bearing compounds such as aniline, amides for ex:- melamine formaldehyde, urea formaldehyde etc. Urea formaldehyde is prepared by condensation reaction between urea and formaldehyde in acidic or alkaline medium. The first product formed during the formation of resin is monomethylol and dimethylol ureas. NH-CH2OH NH-CH2OH │ HCHO │ NH2CONH2 + HCHO C = O …

13/06/1995 · A process of producing an aqueous solution of a sulfonated melamine-formaldehyde resin. The process comprises condensing melamine and formaldehyde or a precursor of formaldehyde (e.g. paraformaldehyde) in an aqueous mixture having a pH in the range of 8-10 to form a reaction mixture containing a condensation product of melamine and

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation. We discussed the thermal stability of MF foam and the effect of different emulsifiers on its

(PDF) Melamine–Formaldehyde Adhesives ResearchGate

https://www.youtube.com/embed/UuTzneD6LK4

The Polyurethane Foams Based on Melamine-formaldehyde

©Smithers Information Ltd. 2017 The Polyurethane Foams Based on Melamine-formaldehyde-cyclohexanone Resins Dorota Głowacz-Czerwonka Faculty …

The microcapsules used for electrophoretic display were prepared by in-situ polymerization. The core material contained electrophoretic particles (phthalocyanine blue and TiO2) and tetrachloroethylene (TCE), and the wall material were made of melamine-formaldehyde resin. The effects of preparation conditions, such as the concentration of

Approximately 1 million metric tons of urea-formaldehyde resin are produced annually. More than 70% of this urea-formaldehyde resin is used by the forest products industry for a variety of purposes.

A two-step organic sol–gel process for the preparation of monodispersed or narrow-dispersed melamine– formaldehyde (MF) resin polymer colloidal spheres in water was developed.

Self-healing microcapsules were synthesized by in situ polymerization with a melamine urea-formaldehyde resin shell and an epoxy resin adhesive. The effects of the key factors, i.e., core–wall ratio, reaction temperature, pH and stirring rate, were investigated by characterizing microcapsule morphology, shell thickness, particle size

Preparation and Characterization of Melamine-Formaldehyde Resin Micro- and Nanocapsules Filled with n-Dodecane. Kongying Zhu School of Materials Science and Engineering, and Tianjin Key Laboratory of Composite and Functional Materials , Tianjin University , Tianjin , China , Hengzhi Qi School of Materials Science and Engineering, and Tianjin Key Laboratory of Composite and …

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse Feng Fu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

examples of thermosetting polymers are Urea -Formaldehyde resin and Melamine – Formaldehyde resins. Preparation and Properties of Phenol-Formaldehyde Resin Reinforced with Recycled Cellulose

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation. We discussed the thermal stability of MF foam and

pH value during microencapsulation had to be lowered in a linear way or in smaller steps to 5.0 or lower. Keywords: thermal properties, microencapsulation, melamine-formaldehyde resin…

374 melamine–formaldehyde resins vol. 10 Because of the high costs of melamine as raw material, the costs for melamine-based resins are, however, much higher than for UF resins.

material safety data sheet MF415 Melamine Formaldehyde Resin Powder – [Distributed] Version No.:6 – Distribution date: 11/24/2009 possible carcinogenic to humans by inhalation.

increased melamine content were significant only for IB strength, but changes in melamine reaction pH in resin preparation resulted in a resin system that had …

Melamine / ˈ m ɛ l ə m iː n / is the organic compound with the formula C 3 H 6 N 6. This white solid is a trimer of cyanamide, with a 1,3,5-triazine skeleton.

Read “Preparation and characterization of microencapsulated LDHs with melamine‐formaldehyde resin and its flame retardant application in epoxy resin, Polymers for Advanced Technologies” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

The preparation is based on an assembly process, with evaporation of an ethanol-water solution containing melamine formaldehyde resin (MF resin) as carbon source, nitrogen source, and chelating agent. Moreover, F127 and Co(NO) are used as template and metallic precursor, respectively.

Abstract. In this study, melamine-formaldehyde microcapsules were prepared viain situ polymerization using peppermint oil as a core material, melamine-formaldehyde as the wall material, Tween 20 as the emulsifier, and poly (vinyl alcohol) as a protective colloid.

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse FengFu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

urea-formaldehyde resin shell and an epoxy resin adhesive. The effects of the key factors, i.e., The effects of the key factors, i.e., core–wall ratio, reaction temperature, pH and stirring rate, were investigated by characterizing

Materials and Methods The preparation of the SMF resin 178 g of formaldehyde solution (37% wt %) and 1.3 g of borax (0.3 wt %) were put into a reactor.

PDF On Aug 6, 2003, A Pizzi and others published Melamine–Formaldehyde Adhesives . See all › 12 during resin preparation at which addition of a drop of MF reaction mixture to a test tube

Preparation of Nitrogen-Doped Carbon Nanotubes with

Melamine formaldehyde (MF) foam is a kind of fire-retardant material, which has many excellent properties. In this paper, the effect of foaming agent on foam-cell structure of MF foam was discussed, along with the compressive property, the water absorption and its thermo gravimetric behavior as well as its fire-retardant property behaved by

Effect of emulsion preparation method on microencapsulation of n-octadecane using melamine-formaldehyde pre-polymers M The microcapsules containing n-octadecane as the core material and melamine-formaldehyde resin as the wall material have been synthesized by in situ polymerization method. A systematic study has been carried out to investigate the effect of the method used in the

Melamine-formaldehyde resins constitute the remainder of this class of resins, except for minor amounts of resins that are produced from other aldehydes or amino compounds (especially aniline), or both. Amino resins are often used to modify the properties of other materials.2,3 These resins are added during the pro-cessing of such products as textile fabrics to impart perma-nent press

secondary methylols. In the second sequence of resin synthesis, methylol–melamine and methylol–urea conden-sate into methylene and methylene–ether bridges (Fig. 1).

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation.

Phenol/formaldehyde resins and melamine/formaldehyde resins are standard resins used for many products. The choice of resin depends on the desired properties. The choice of resin depends on theUrea formaldehyde (UF) resin which is one of the most important wood adhesives is a polymeric condensation product of the chemical reaction of formaldehyde with urea, and considered as the most important ype of adhesive resins for the production of particleboards. The present study is aimed to preparation and characterization of urea/ formaldehyde/ Rosa Canina sp. seeds and urea/formaldehyde

Melamine Formaldehyde Powder Resin Melfores 103 P is a powder Melamine formaldehyde resin used for glazing of amino moulded Distilled or de‐ionized water is recommended for the preparation of resin solution. The dissolution would

Melamine-formaldehyde resin was synthesized to be used with the synthesized hyperbranched resins, and it was successfully modified by all hyperbranched resins at a ratio of 3:1.

A melamine-formaldehyde resin consisting essentially of 2.0 to 2.5 mols of formaldehyde per mol of melamine and having a miscibility of one part by weight in 0.5 to 1.5 parts by weight of water at 25 C., and prepared by the process of claim 1.

Previous article in issue: Simultaneous polymerization and formation of polyacetylene film on the surface of concentrated soluble Ziegler-type catalyst solution

the laboratory with a formaldehyde/(urea + melamine) mole ratio of 1.48. The physical characteristics of The physical characteristics of the MUF resin including nonvolatile solids, specific gravity, pH, free formaldehyde, and viscosity, etc., were

The Decomposition Process of Melamine Formaldehyde Cores 357 Infrared Spectroscopy A Bruker Equinox 55/s infrared spectrometer was employed for …

Synthesis and Characterization of Sucrose Melamine

Characterization and Performance of Melamine Enhanced Urea Formaldehyde Resin for Bonding Southern Pine Particleboard Qi-Ning Sun,1 Chung-Yun Hse,2 Todd F. Shupe1

Phenol–melamine–formaldehyde resins (PMF-resins) show, in some respects, better properties than the corresponding MF- and PF-condensates. 59, 69, 70 The preparation of these resins is described in various patents and publications. 71–81

Melamine-urea-formaldehyde is a synthetic resin belonging to the amino resin family. Amino resins are thermosetting polymers made by combining an aldehyde with a compound containing an amino (-NH,) group (Amit Mukherjee & Subrata Ghosh, 1996).

Melamine and formaldehyde are used in the production of polymers, so-called melamine resins, which are used to manufacture kitchen dishes such as plates, cups or bowls as well as kitchen utensils such as cooking spoons or spatulas.

US3470134A Preparation of melamine-formaldehyde resins

Synthesis and Thermal Degradation Studies of Melamine

https://www.youtube.com/embed/1SH_8GpLZy4

Preparation, molecular weight determ ination and structure elucidation of melamine-urea formaldehyde, melamine-methylurea formaldehyde and melamine-dimethylurea formaldehyde polymer resins with IR spectroscopy Man Singh Chem istry Research Lab, Deshbandhu College, Uni versity of Delhi, New Delhi 11 0019, India Received 5 Decell/ber 2003; revised 12 May 2004 Melami ne …

The resin used was a melamine-formaldehyde resin containing 3.3 moles of formaldehyde for each mole of melamine, prepared as described in the first paragraph of Example 1. Upon the addition of relatively small amounts of hydrochloric acid to the solution a precipitation of a white amorphous resin occurs, and this condition persists until a pHl of about 3.5 is obtained, corresponding to about 0

Melamine formaldehyde (MF) resin was synthesized by the reaction between melamine and formaldehyde under alkaline condition in tetrohydrofuran medium with 1:3 melamine to formaldehyde molar ratio. The synthesized resins were characterized by

The resin system with an alkyd/melamine ratio of 70:30 and 30 wt% epoxy resin had the lowest apparent activation energy of 141.5 kJ/mol. Liu and Zhu (2014) investigated the formaldehyde and volatile organic compound (VOC) emissions from wood-based panels coated with nanomaterial-modified melamine impregnate.

9/11/2014 · In case of melamine formaldehyde resin the value of “a” is usually 0.6 and “K” is 0.076. In this experiment, the values of “ K ” and “ a ” were based on the behavior of homopolymers in the aqueous phase.The values of these constants depend upon the polymer solvent interactions.

MUF resin preparation The MUF resin preparation was adopted from Bono et al. (2003)9. The main materials were used to produce MUF resin are formaldehyde, melamine, and urea respectively. In brief, 100 mL of 37% formalin was poured in a 500 mL three-necked flask and required amounts of melamine, urea were added under vigorous stirring. The temperature of the mixture was maintained …

formaldehyde with melamine (1,3,5-triazine-2,4,6-triamine) [17]. These melamine-based resins have These melamine-based resins have found several applications, since melamine allows the obtaining of polymers with relatively high

Melamine formaldehyde curing studies and reaction

Preparation of carbon dioxide adsorbents from the chemical

The aim of this research was to prepare and analyze suitable microcapsules for the chosen end use—that is, bow-ties. The produced microcapsules were composed of melamine formaldehyde microcapsules with fragrance oils in the core. Regarding the properties, the surface morphology (studied by Scanning electron microscopy (SEM)), thermal

Melamine–formaldehyde (MF) and melamine–urea–formaldehyde (MUF) resins are some of the most widely used adhesives for exterior and semi-exterior wood panels and for the preparation and bonding of low- and high-pressure paper laminates and overlays.

Formaldehyde (MUF) resin is selected as the resin for wood adhesive production because of less costly and high water resistant compared to Melamine Formaldehyde (MF) and Urea Formaldehyde (UF) resins (Dunky, 2003).

Melamine-formaldehyde resin Britannica.com

Comparative Study of Synthesis Procedures for Urea – Formaldehyde Resins (Part I) Mathew Obichukwu EDOGA 64 Keywords Urea-Formaldehyde resin, Synthesis- …

5/09/2013 · A new, easy and cost-effective synthetic procedure for the preparation of thermosetting melamine-based epoxy resins is reported. By this innovative synthetic method, different kinds of resins can be obtained just by mixing the reagents in the presence of a catalyst without solvent and with mild curing conditions. the power of habit by charles duhigg free pdf

Microencapsulation of butyl stearate with melamine

SYNTHESIS OF OIL BASED HYPERBRANCHED RESINS AND THEIR

Preparation and characterization of microencapsulated LDHs

Melamine-Dimethylurea-Formaldehyde Co-Condensations A

Preparation of Melamine-Formaldehyde Resin Microcapsules

Melamine Formaldehyde Powder Resin Mena Chemicals

Study of Preparation and Properties of Fire-Retardant

Release of melamine and formaldehyde from dishes and

Yan Jiang, Wanli Zhou, Mengjin Jiang, Pengqing Liu and Jianjun Xu, Flame retardant study of formalized polyvinyl alcohol fiber coated with melamine formaldehyde resins and the synergistic effect of copper ions, Polymer Degradation and Stability, 144, (331), (2017).

material safety data sheet MF415 Melamine Formaldehyde Resin Powder – [Distributed] Version No.:6 – Distribution date: 11/24/2009 possible carcinogenic to humans by inhalation.

13/06/1995 · A process of producing an aqueous solution of a sulfonated melamine-formaldehyde resin. The process comprises condensing melamine and formaldehyde or a precursor of formaldehyde (e.g. paraformaldehyde) in an aqueous mixture having a pH in the range of 8-10 to form a reaction mixture containing a condensation product of melamine and

PDF On Aug 6, 2003, A Pizzi and others published Melamine–Formaldehyde Adhesives . See all › 12 during resin preparation at which addition of a drop of MF reaction mixture to a test tube

A melamine-formaldehyde resin consisting essentially of 2.0 to 2.5 mols of formaldehyde per mol of melamine and having a miscibility of one part by weight in 0.5 to 1.5 parts by weight of water at 25 C., and prepared by the process of claim 1.

Melamine formaldehyde (MF) foam is a kind of fire-retardant material, which has many excellent properties. In this paper, the effect of foaming agent on foam-cell structure of MF foam was discussed, along with the compressive property, the water absorption and its thermo gravimetric behavior as well as its fire-retardant property behaved by

Melamine-urea-formaldehyde is a synthetic resin belonging to the amino resin family. Amino resins are thermosetting polymers made by combining an aldehyde with a compound containing an amino (-NH,) group (Amit Mukherjee & Subrata Ghosh, 1996).

Effect of emulsion preparation method on microencapsulation of n-octadecane using melamine-formaldehyde pre-polymers M The microcapsules containing n-octadecane as the core material and melamine-formaldehyde resin as the wall material have been synthesized by in situ polymerization method. A systematic study has been carried out to investigate the effect of the method used in the

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse Feng Fu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

Approximately 1 million metric tons of urea-formaldehyde resin are produced annually. More than 70% of this urea-formaldehyde resin is used by the forest products industry for a variety of purposes.

Melamine-formaldehyde resin was synthesized to be used with the synthesized hyperbranched resins, and it was successfully modified by all hyperbranched resins at a ratio of 3:1.

Melamine formaldehyde microcapsules with fragrance core

Synthesis and characterization of sucrose-melamine

Read “Preparation and characterization of microencapsulated LDHs with melamine‐formaldehyde resin and its flame retardant application in epoxy resin, Polymers for Advanced Technologies” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

Materials and Methods The preparation of the SMF resin 178 g of formaldehyde solution (37% wt %) and 1.3 g of borax (0.3 wt %) were put into a reactor.

Phenol–melamine–formaldehyde resins (PMF-resins) show, in some respects, better properties than the corresponding MF- and PF-condensates. 59, 69, 70 The preparation of these resins is described in various patents and publications. 71–81

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation. We discussed the thermal stability of MF foam and

Characterization and performance of melamine enhanced urea

Study of Preparation and Properties of Fire-Retardant

Melamine Formaldehyde Powder Resin Melfores 103 P is a powder Melamine formaldehyde resin used for glazing of amino moulded Distilled or de‐ionized water is recommended for the preparation of resin solution. The dissolution would

Comparative Study of Synthesis Procedures for Urea – Formaldehyde Resins (Part I) Mathew Obichukwu EDOGA 64 Keywords Urea-Formaldehyde resin, Synthesis- …

Effect of emulsion preparation method on microencapsulation of n-octadecane using melamine-formaldehyde pre-polymers M The microcapsules containing n-octadecane as the core material and melamine-formaldehyde resin as the wall material have been synthesized by in situ polymerization method. A systematic study has been carried out to investigate the effect of the method used in the

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation.

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation. We discussed the thermal stability of MF foam and the effect of different emulsifiers on its

Previous article in issue: Simultaneous polymerization and formation of polyacetylene film on the surface of concentrated soluble Ziegler-type catalyst solution

9/11/2014 · In case of melamine formaldehyde resin the value of “a” is usually 0.6 and “K” is 0.076. In this experiment, the values of “ K ” and “ a ” were based on the behavior of homopolymers in the aqueous phase.The values of these constants depend upon the polymer solvent interactions.

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse Feng Fu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

Preparation of Nitrogen-Doped Carbon Nanotubes with Different Morphologies from Melamine-Formaldehyde Resin Yi Yao † ‡ , Bingqing Zhang § ∥ , Jingying Shi † § , and Qihua Yang * † † State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, Chinese Academy of Sciences , 457 Zhongshan Road, Dalian 116023, China

pH value during microencapsulation had to be lowered in a linear way or in smaller steps to 5.0 or lower. Keywords: thermal properties, microencapsulation, melamine-formaldehyde resin…

3.3 Waste rubber powder preparation 25 3.4 Treatment of waste rubber powder 25 3.4.1 Treatment of waste rubber powder with 20% nitric acid 25-26 3.4.2 Treatment of waste rubber powder with 30% hydrogen peroxide 26 3.4.3 Treatment of waste rubber powder with acetone 26-27 3.5 Melamine urea formaldehyde based resin preparation 27 3.6 Optimization and formulation of melamine urea 27 …

Abstract. In this study, melamine-formaldehyde microcapsules were prepared viain situ polymerization using peppermint oil as a core material, melamine-formaldehyde as the wall material, Tween 20 as the emulsifier, and poly (vinyl alcohol) as a protective colloid.

SYNTHESIS OF OIL BASED HYPERBRANCHED RESINS AND THEIR

Melamine formaldehyde curing studies and reaction

Abstract. In this study, melamine-formaldehyde microcapsules were prepared viain situ polymerization using peppermint oil as a core material, melamine-formaldehyde as the wall material, Tween 20 as the emulsifier, and poly (vinyl alcohol) as a protective colloid.

Melamine-urea-formaldehyde is a synthetic resin belonging to the amino resin family. Amino resins are thermosetting polymers made by combining an aldehyde with a compound containing an amino (-NH,) group (Amit Mukherjee & Subrata Ghosh, 1996).

–Formaldehyde –Melamine formaldehyde resin –Phenol-formaldehyde resins –Urea formaldehyde resin IHS Markit Formaldehyde & Resins. Title: IHS PDF Report Created Date: 9/29/2017 8:13:17 AM

A two-step organic sol–gel process for the preparation of monodispersed or narrow-dispersed melamine– formaldehyde (MF) resin polymer colloidal spheres in water was developed.

increased melamine content were significant only for IB strength, but changes in melamine reaction pH in resin preparation resulted in a resin system that had …

nitrogen bearing compounds such as aniline, amides for ex:- melamine formaldehyde, urea formaldehyde etc. Urea formaldehyde is prepared by condensation reaction between urea and formaldehyde in acidic or alkaline medium. The first product formed during the formation of resin is monomethylol and dimethylol ureas. NH-CH2OH NH-CH2OH │ HCHO │ NH2CONH2 HCHO C = O …

Melamine-formaldehyde resin Britannica.com

Optimization of preparation conditions for melamine urea

Formaldehyde (MUF) resin is selected as the resin for wood adhesive production because of less costly and high water resistant compared to Melamine Formaldehyde (MF) and Urea Formaldehyde (UF) resins (Dunky, 2003).

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse FengFu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

Polymer Dr. N. K. Patel EXPERIMENT: 5 PREPARATION OF MELAMINE FORMALDEHYDE RESIN Aim: To prepare melamine formaldehyde resin. Requirements: Melamine, formaline

Melamine and formaldehyde are used in the production of polymers, so-called melamine resins, which are used to manufacture kitchen dishes such as plates, cups or bowls as well as kitchen utensils such as cooking spoons or spatulas.

melamine formaldehyde Publications PubFacts

Monodispersed or narrow-dispersed melamine–formaldehyde

The microcapsules used for electrophoretic display were prepared by in-situ polymerization. The core material contained electrophoretic particles (phthalocyanine blue and TiO2) and tetrachloroethylene (TCE), and the wall material were made of melamine-formaldehyde resin. The effects of preparation conditions, such as the concentration of

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse FengFu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

Melamine formaldehyde (MF) foam is a kind of fire-retardant material, which has many excellent properties. In this paper, the effect of foaming agent on foam-cell structure of MF foam was discussed, along with the compressive property, the water absorption and its thermo gravimetric behavior as well as its fire-retardant property behaved by

PDF On Aug 6, 2003, A Pizzi and others published Melamine–Formaldehyde Adhesives . See all › 12 during resin preparation at which addition of a drop of MF reaction mixture to a test tube

Synthesis and Characterization of Melamine Formaldehyde

Melamine-formaldehyde resin Britannica.com

Melamine-formaldehyde resins constitute the remainder of this class of resins, except for minor amounts of resins that are produced from other aldehydes or amino compounds (especially aniline), or both. Amino resins are often used to modify the properties of other materials.2,3 These resins are added during the pro-cessing of such products as textile fabrics to impart perma-nent press

Effect of emulsion preparation method on microencapsulation of n-octadecane using melamine-formaldehyde pre-polymers M The microcapsules containing n-octadecane as the core material and melamine-formaldehyde resin as the wall material have been synthesized by in situ polymerization method. A systematic study has been carried out to investigate the effect of the method used in the

The microcapsules used for electrophoretic display were prepared by in-situ polymerization. The core material contained electrophoretic particles (phthalocyanine blue and TiO2) and tetrachloroethylene (TCE), and the wall material were made of melamine-formaldehyde resin. The effects of preparation conditions, such as the concentration of

Materials and Methods The preparation of the SMF resin 178 g of formaldehyde solution (37% wt %) and 1.3 g of borax (0.3 wt %) were put into a reactor.

Melamine-urea-formaldehyde is a synthetic resin belonging to the amino resin family. Amino resins are thermosetting polymers made by combining an aldehyde with a compound containing an amino (-NH,) group (Amit Mukherjee & Subrata Ghosh, 1996).

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation. We discussed the thermal stability of MF foam and the effect of different emulsifiers on its

material safety data sheet MF415 Melamine Formaldehyde Resin Powder – [Distributed] Version No.:6 – Distribution date: 11/24/2009 possible carcinogenic to humans by inhalation.

Melamine resin or melamine formaldehyde (also shortened to melamine) is a hard, thermosetting plastic material made from melamine and formaldehyde by polymerization. [1] In its butylated form, it is dissolved in n -butanol and xylene .

MUF resin preparation The MUF resin preparation was adopted from Bono et al. (2003)9. The main materials were used to produce MUF resin are formaldehyde, melamine, and urea respectively. In brief, 100 mL of 37% formalin was poured in a 500 mL three-necked flask and required amounts of melamine, urea were added under vigorous stirring. The temperature of the mixture was maintained …

5/09/2013 · A new, easy and cost-effective synthetic procedure for the preparation of thermosetting melamine-based epoxy resins is reported. By this innovative synthetic method, different kinds of resins can be obtained just by mixing the reagents in the presence of a catalyst without solvent and with mild curing conditions.

Yan Jiang, Wanli Zhou, Mengjin Jiang, Pengqing Liu and Jianjun Xu, Flame retardant study of formalized polyvinyl alcohol fiber coated with melamine formaldehyde resins and the synergistic effect of copper ions, Polymer Degradation and Stability, 144, (331), (2017).

Melamine Formaldehyde Powder Resin Melfores 103 P is a powder Melamine formaldehyde resin used for glazing of amino moulded Distilled or de‐ionized water is recommended for the preparation of resin solution. The dissolution would

The Polyurethane Foams Based on Melamine-formaldehyde

US2345543A Cationic melamine-formaldehyde resin solution

Phenol–melamine–formaldehyde resins (PMF-resins) show, in some respects, better properties than the corresponding MF- and PF-condensates. 59, 69, 70 The preparation of these resins is described in various patents and publications. 71–81

the laboratory with a formaldehyde/(urea melamine) mole ratio of 1.48. The physical characteristics of The physical characteristics of the MUF resin including nonvolatile solids, specific gravity, pH, free formaldehyde, and viscosity, etc., were

Preparation of Nitrogen-Doped Carbon Nanotubes with Different Morphologies from Melamine-Formaldehyde Resin Yi Yao † ‡ , Bingqing Zhang § ∥ , Jingying Shi † § , and Qihua Yang * † † State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, Chinese Academy of Sciences , 457 Zhongshan Road, Dalian 116023, China

©Smithers Information Ltd. 2017 The Polyurethane Foams Based on Melamine-formaldehyde-cyclohexanone Resins Dorota Głowacz-Czerwonka Faculty …

Melamine Formaldehyde Powder Resin Melfores 103 P is a powder Melamine formaldehyde resin used for glazing of amino moulded Distilled or de‐ionized water is recommended for the preparation of resin solution. The dissolution would

374 melamine–formaldehyde resins vol. 10 Because of the high costs of melamine as raw material, the costs for melamine-based resins are, however, much higher than for UF resins.

Polymers 2017, 9, 109 3 of 12 2.1.2. Samples for Melamine-Formaldehyde (MF) Reactions under Weak Acidic Conditions The pH of 16.22 g formaldehyde aqueous solution (37%) was pre …

Formaldehyde (MUF) resin is selected as the resin for wood adhesive production because of less costly and high water resistant compared to Melamine Formaldehyde (MF) and Urea Formaldehyde (UF) resins (Dunky, 2003).

Melamine / ˈ m ɛ l ə m iː n / is the organic compound with the formula C 3 H 6 N 6. This white solid is a trimer of cyanamide, with a 1,3,5-triazine skeleton.

The aim of this research was to prepare and analyze suitable microcapsules for the chosen end use—that is, bow-ties. The produced microcapsules were composed of melamine formaldehyde microcapsules with fragrance oils in the core. Regarding the properties, the surface morphology (studied by Scanning electron microscopy (SEM)), thermal

pH value during microencapsulation had to be lowered in a linear way or in smaller steps to 5.0 or lower. Keywords: thermal properties, microencapsulation, melamine-formaldehyde resin…

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse Feng Fu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

The resin system with an alkyd/melamine ratio of 70:30 and 30 wt% epoxy resin had the lowest apparent activation energy of 141.5 kJ/mol. Liu and Zhu (2014) investigated the formaldehyde and volatile organic compound (VOC) emissions from wood-based panels coated with nanomaterial-modified melamine impregnate.

Read “Preparation and characterization of microencapsulated LDHs with melamine‐formaldehyde resin and its flame retardant application in epoxy resin, Polymers for Advanced Technologies” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

Melamine formaldehyde curing studies and reaction

Synthesis and Characterization of Melamine Formaldehyde

Melamine formaldehyde (MF) foam is a kind of fire-retardant material, which has many excellent properties. In this paper, the effect of foaming agent on foam-cell structure of MF foam was discussed, along with the compressive property, the water absorption and its thermo gravimetric behavior as well as its fire-retardant property behaved by

Polymer Dr. N. K. Patel EXPERIMENT: 5 PREPARATION OF MELAMINE FORMALDEHYDE RESIN Aim: To prepare melamine formaldehyde resin. Requirements: Melamine, formaline

Preparation of Nitrogen-Doped Carbon Nanotubes with Different Morphologies from Melamine-Formaldehyde Resin Yi Yao † ‡ , Bingqing Zhang § ∥ , Jingying Shi † § , and Qihua Yang * † † State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, Chinese Academy of Sciences , 457 Zhongshan Road, Dalian 116023, China

secondary methylols. In the second sequence of resin synthesis, methylol–melamine and methylol–urea conden-sate into methylene and methylene–ether bridges (Fig. 1).

374 melamine–formaldehyde resins vol. 10 Because of the high costs of melamine as raw material, the costs for melamine-based resins are, however, much higher than for UF resins.

Comparative Study of Synthesis Procedures for Urea – Formaldehyde Resins (Part I) Mathew Obichukwu EDOGA 64 Keywords Urea-Formaldehyde resin, Synthesis- …

The microcapsules used for electrophoretic display were prepared by in-situ polymerization. The core material contained electrophoretic particles (phthalocyanine blue and TiO2) and tetrachloroethylene (TCE), and the wall material were made of melamine-formaldehyde resin. The effects of preparation conditions, such as the concentration of

–Formaldehyde –Melamine formaldehyde resin –Phenol-formaldehyde resins –Urea formaldehyde resin IHS Markit Formaldehyde & Resins. Title: IHS PDF Report Created Date: 9/29/2017 8:13:17 AM

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation. We discussed the thermal stability of MF foam and the effect of different emulsifiers on its

Approximately 1 million metric tons of urea-formaldehyde resin are produced annually. More than 70% of this urea-formaldehyde resin is used by the forest products industry for a variety of purposes.

Study of Preparation and Properties of Fire-Retardant

Melamine-formaldehyde resin Britannica.com

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse FengFu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

Preparation, molecular weight determ ination and structure elucidation of melamine-urea formaldehyde, melamine-methylurea formaldehyde and melamine-dimethylurea formaldehyde polymer resins with IR spectroscopy Man Singh Chem istry Research Lab, Deshbandhu College, Uni versity of Delhi, New Delhi 11 0019, India Received 5 Decell/ber 2003; revised 12 May 2004 Melami ne …

Melamine Formaldehyde Powder Resin Melfores 103 P is a powder Melamine formaldehyde resin used for glazing of amino moulded Distilled or de‐ionized water is recommended for the preparation of resin solution. The dissolution would

Materials and Methods The preparation of the SMF resin 178 g of formaldehyde solution (37% wt %) and 1.3 g of borax (0.3 wt %) were put into a reactor.

MUF resin preparation The MUF resin preparation was adopted from Bono et al. (2003)9. The main materials were used to produce MUF resin are formaldehyde, melamine, and urea respectively. In brief, 100 mL of 37% formalin was poured in a 500 mL three-necked flask and required amounts of melamine, urea were added under vigorous stirring. The temperature of the mixture was maintained …

Approximately 1 million metric tons of urea-formaldehyde resin are produced annually. More than 70% of this urea-formaldehyde resin is used by the forest products industry for a variety of purposes.

Formaldehyde (MUF) resin is selected as the resin for wood adhesive production because of less costly and high water resistant compared to Melamine Formaldehyde (MF) and Urea Formaldehyde (UF) resins (Dunky, 2003).

Melamine–formaldehyde (MF) and melamine–urea–formaldehyde (MUF) resins are some of the most widely used adhesives for exterior and semi-exterior wood panels and for the preparation and bonding of low- and high-pressure paper laminates and overlays.

examples of thermosetting polymers are Urea -Formaldehyde resin and Melamine – Formaldehyde resins. Preparation and Properties of Phenol-Formaldehyde Resin Reinforced with Recycled Cellulose

Melamine Formaldehyde Powder Resin Mena Chemicals

Synthesis and Thermal Degradation Studies of Melamine

Melamine–formaldehyde (MF) and melamine–urea–formaldehyde (MUF) resins are some of the most widely used adhesives for exterior and semi-exterior wood panels and for the preparation and bonding of low- and high-pressure paper laminates and overlays.

Melamine formaldehyde (MF) foam is a kind of fire-retardant material, which has many excellent properties. In this paper, the effect of foaming agent on foam-cell structure of MF foam was discussed, along with the compressive property, the water absorption and its thermo gravimetric behavior as well as its fire-retardant property behaved by

increased melamine content were significant only for IB strength, but changes in melamine reaction pH in resin preparation resulted in a resin system that had …

formaldehyde with melamine (1,3,5-triazine-2,4,6-triamine) [17]. These melamine-based resins have These melamine-based resins have found several applications, since melamine allows the obtaining of polymers with relatively high

Comparative Study of Synthesis Procedures for Urea – Formaldehyde Resins (Part I) Mathew Obichukwu EDOGA 64 Keywords Urea-Formaldehyde resin, Synthesis- …

A melamine-formaldehyde resin consisting essentially of 2.0 to 2.5 mols of formaldehyde per mol of melamine and having a miscibility of one part by weight in 0.5 to 1.5 parts by weight of water at 25 C., and prepared by the process of claim 1.

©Smithers Information Ltd. 2017 The Polyurethane Foams Based on Melamine-formaldehyde-cyclohexanone Resins Dorota Głowacz-Czerwonka Faculty …

secondary methylols. In the second sequence of resin synthesis, methylol–melamine and methylol–urea conden-sate into methylene and methylene–ether bridges (Fig. 1).

Urea formaldehyde (UF) resin which is one of the most important wood adhesives is a polymeric condensation product of the chemical reaction of formaldehyde with urea, and considered as the most important ype of adhesive resins for the production of particleboards. The present study is aimed to preparation and characterization of urea/ formaldehyde/ Rosa Canina sp. seeds and urea/formaldehyde

The preparation is based on an assembly process, with evaporation of an ethanol-water solution containing melamine formaldehyde resin (MF resin) as carbon source, nitrogen source, and chelating agent. Moreover, F127 and Co(NO) are used as template and metallic precursor, respectively.

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation.

Formaldehyde (MUF) resin is selected as the resin for wood adhesive production because of less costly and high water resistant compared to Melamine Formaldehyde (MF) and Urea Formaldehyde (UF) resins (Dunky, 2003).

The resin system with an alkyd/melamine ratio of 70:30 and 30 wt% epoxy resin had the lowest apparent activation energy of 141.5 kJ/mol. Liu and Zhu (2014) investigated the formaldehyde and volatile organic compound (VOC) emissions from wood-based panels coated with nanomaterial-modified melamine impregnate.

Curing kinetics study of melamine–urea–formaldehyde resin

Melamine resin Wikipedia

Phenol–melamine–formaldehyde resins (PMF-resins) show, in some respects, better properties than the corresponding MF- and PF-condensates. 59, 69, 70 The preparation of these resins is described in various patents and publications. 71–81

3.3 Waste rubber powder preparation 25 3.4 Treatment of waste rubber powder 25 3.4.1 Treatment of waste rubber powder with 20% nitric acid 25-26 3.4.2 Treatment of waste rubber powder with 30% hydrogen peroxide 26 3.4.3 Treatment of waste rubber powder with acetone 26-27 3.5 Melamine urea formaldehyde based resin preparation 27 3.6 Optimization and formulation of melamine urea 27 …

increased melamine content were significant only for IB strength, but changes in melamine reaction pH in resin preparation resulted in a resin system that had …

Melamine / ˈ m ɛ l ə m iː n / is the organic compound with the formula C 3 H 6 N 6. This white solid is a trimer of cyanamide, with a 1,3,5-triazine skeleton.

MUF resin preparation The MUF resin preparation was adopted from Bono et al. (2003)9. The main materials were used to produce MUF resin are formaldehyde, melamine, and urea respectively. In brief, 100 mL of 37% formalin was poured in a 500 mL three-necked flask and required amounts of melamine, urea were added under vigorous stirring. The temperature of the mixture was maintained …

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse Feng Fu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

–Formaldehyde –Melamine formaldehyde resin –Phenol-formaldehyde resins –Urea formaldehyde resin IHS Markit Formaldehyde & Resins. Title: IHS PDF Report Created Date: 9/29/2017 8:13:17 AM

Preparation, molecular weight determ ination and structure elucidation of melamine-urea formaldehyde, melamine-methylurea formaldehyde and melamine-dimethylurea formaldehyde polymer resins with IR spectroscopy Man Singh Chem istry Research Lab, Deshbandhu College, Uni versity of Delhi, New Delhi 11 0019, India Received 5 Decell/ber 2003; revised 12 May 2004 Melami ne …

Melamine resin or melamine formaldehyde (also shortened to melamine) is a hard, thermosetting plastic material made from melamine and formaldehyde by polymerization. [1] In its butylated form, it is dissolved in n -butanol and xylene .

Polymer Dr. N. K. Patel EXPERIMENT: 5 PREPARATION OF MELAMINE FORMALDEHYDE RESIN Aim: To prepare melamine formaldehyde resin. Requirements: Melamine, formaline

Materials and Methods The preparation of the SMF resin 178 g of formaldehyde solution (37% wt %) and 1.3 g of borax (0.3 wt %) were put into a reactor.

The microcapsules used for electrophoretic display were prepared by in-situ polymerization. The core material contained electrophoretic particles (phthalocyanine blue and TiO2) and tetrachloroethylene (TCE), and the wall material were made of melamine-formaldehyde resin. The effects of preparation conditions, such as the concentration of

Yan Jiang, Wanli Zhou, Mengjin Jiang, Pengqing Liu and Jianjun Xu, Flame retardant study of formalized polyvinyl alcohol fiber coated with melamine formaldehyde resins and the synergistic effect of copper ions, Polymer Degradation and Stability, 144, (331), (2017).

(PDF) Melamine–Formaldehyde Adhesives ResearchGate

Preparation of Nitrogen-Doped Carbon Nanotubes with

Yan Jiang, Wanli Zhou, Mengjin Jiang, Pengqing Liu and Jianjun Xu, Flame retardant study of formalized polyvinyl alcohol fiber coated with melamine formaldehyde resins and the synergistic effect of copper ions, Polymer Degradation and Stability, 144, (331), (2017).

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation. We discussed the thermal stability of MF foam and the effect of different emulsifiers on its

Preparation of Nitrogen-Doped Carbon Nanotubes with Different Morphologies from Melamine-Formaldehyde Resin Yi Yao † ‡ , Bingqing Zhang § ∥ , Jingying Shi † § , and Qihua Yang * † † State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, Chinese Academy of Sciences , 457 Zhongshan Road, Dalian 116023, China

Urea formaldehyde (UF) resin which is one of the most important wood adhesives is a polymeric condensation product of the chemical reaction of formaldehyde with urea, and considered as the most important ype of adhesive resins for the production of particleboards. The present study is aimed to preparation and characterization of urea/ formaldehyde/ Rosa Canina sp. seeds and urea/formaldehyde

Melamine-Dimethylurea-Formaldehyde Co-Condensations A

Preparation of Monodisperse Submicrometer Carbon Spheres

A melamine-formaldehyde resin consisting essentially of 2.0 to 2.5 mols of formaldehyde per mol of melamine and having a miscibility of one part by weight in 0.5 to 1.5 parts by weight of water at 25 C., and prepared by the process of claim 1.

Self-healing microcapsules were synthesized by in situ polymerization with a melamine urea-formaldehyde resin shell and an epoxy resin adhesive. The effects of the key factors, i.e., core–wall ratio, reaction temperature, pH and stirring rate, were investigated by characterizing microcapsule morphology, shell thickness, particle size

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation.

374 melamine–formaldehyde resins vol. 10 Because of the high costs of melamine as raw material, the costs for melamine-based resins are, however, much higher than for UF resins.

A two-step organic sol–gel process for the preparation of monodispersed or narrow-dispersed melamine– formaldehyde (MF) resin polymer colloidal spheres in water was developed.

Polymers 2017, 9, 109 3 of 12 2.1.2. Samples for Melamine-Formaldehyde (MF) Reactions under Weak Acidic Conditions The pH of 16.22 g formaldehyde aqueous solution (37%) was pre …

Melamine formaldehyde (MF) foam is a kind of fire-retardant material, which has many excellent properties. In this paper, the effect of foaming agent on foam-cell structure of MF foam was discussed, along with the compressive property, the water absorption and its thermo gravimetric behavior as well as its fire-retardant property behaved by

Abstract. In this study, melamine-formaldehyde microcapsules were prepared viain situ polymerization using peppermint oil as a core material, melamine-formaldehyde as the wall material, Tween 20 as the emulsifier, and poly (vinyl alcohol) as a protective colloid.

nitrogen bearing compounds such as aniline, amides for ex:- melamine formaldehyde, urea formaldehyde etc. Urea formaldehyde is prepared by condensation reaction between urea and formaldehyde in acidic or alkaline medium. The first product formed during the formation of resin is monomethylol and dimethylol ureas. NH-CH2OH NH-CH2OH │ HCHO │ NH2CONH2 HCHO C = O …

Melamine-Dimethylurea-Formaldehyde Co-Condensations A

Melamine-formaldehyde resin Britannica.com

©Smithers Information Ltd. 2017 The Polyurethane Foams Based on Melamine-formaldehyde-cyclohexanone Resins Dorota Głowacz-Czerwonka Faculty …

nitrogen bearing compounds such as aniline, amides for ex:- melamine formaldehyde, urea formaldehyde etc. Urea formaldehyde is prepared by condensation reaction between urea and formaldehyde in acidic or alkaline medium. The first product formed during the formation of resin is monomethylol and dimethylol ureas. NH-CH2OH NH-CH2OH │ HCHO │ NH2CONH2 HCHO C = O …

A two-step organic sol–gel process for the preparation of monodispersed or narrow-dispersed melamine– formaldehyde (MF) resin polymer colloidal spheres in water was developed.

Melamine-formaldehyde resin was synthesized to be used with the synthesized hyperbranched resins, and it was successfully modified by all hyperbranched resins at a ratio of 3:1.

3.3 Waste rubber powder preparation 25 3.4 Treatment of waste rubber powder 25 3.4.1 Treatment of waste rubber powder with 20% nitric acid 25-26 3.4.2 Treatment of waste rubber powder with 30% hydrogen peroxide 26 3.4.3 Treatment of waste rubber powder with acetone 26-27 3.5 Melamine urea formaldehyde based resin preparation 27 3.6 Optimization and formulation of melamine urea 27 …

urea-formaldehyde resin shell and an epoxy resin adhesive. The effects of the key factors, i.e., The effects of the key factors, i.e., core–wall ratio, reaction temperature, pH and stirring rate, were investigated by characterizing

Synthesis and Thermal Degradation Studies of Melamine

(PDF) Melamine–Formaldehyde Adhesives ResearchGate

The microcapsules used for electrophoretic display were prepared by in-situ polymerization. The core material contained electrophoretic particles (phthalocyanine blue and TiO2) and tetrachloroethylene (TCE), and the wall material were made of melamine-formaldehyde resin. The effects of preparation conditions, such as the concentration of

9/11/2014 · In case of melamine formaldehyde resin the value of “a” is usually 0.6 and “K” is 0.076. In this experiment, the values of “ K ” and “ a ” were based on the behavior of homopolymers in the aqueous phase.The values of these constants depend upon the polymer solvent interactions.

Comparative Study of Synthesis Procedures for Urea – Formaldehyde Resins (Part I) Mathew Obichukwu EDOGA 64 Keywords Urea-Formaldehyde resin, Synthesis- …

Melamine Formaldehyde Powder Resin Melfores 103 P is a powder Melamine formaldehyde resin used for glazing of amino moulded Distilled or de‐ionized water is recommended for the preparation of resin solution. The dissolution would

Melamine-formaldehyde resins constitute the remainder of this class of resins, except for minor amounts of resins that are produced from other aldehydes or amino compounds (especially aniline), or both. Amino resins are often used to modify the properties of other materials.2,3 These resins are added during the pro-cessing of such products as textile fabrics to impart perma-nent press

Melamine resin or melamine formaldehyde (also shortened to melamine) is a hard, thermosetting plastic material made from melamine and formaldehyde by polymerization. [1] In its butylated form, it is dissolved in n -butanol and xylene .

Melamine and formaldehyde are used in the production of polymers, so-called melamine resins, which are used to manufacture kitchen dishes such as plates, cups or bowls as well as kitchen utensils such as cooking spoons or spatulas.

The resin used was a melamine-formaldehyde resin containing 3.3 moles of formaldehyde for each mole of melamine, prepared as described in the first paragraph of Example 1. Upon the addition of relatively small amounts of hydrochloric acid to the solution a precipitation of a white amorphous resin occurs, and this condition persists until a pHl of about 3.5 is obtained, corresponding to about 0

PDF On Aug 6, 2003, A Pizzi and others published Melamine–Formaldehyde Adhesives . See all › 12 during resin preparation at which addition of a drop of MF reaction mixture to a test tube

material safety data sheet MF415 Melamine Formaldehyde Resin Powder – [Distributed] Version No.:6 – Distribution date: 11/24/2009 possible carcinogenic to humans by inhalation.

pH value during microencapsulation had to be lowered in a linear way or in smaller steps to 5.0 or lower. Keywords: thermal properties, microencapsulation, melamine-formaldehyde resin…

Synthesis and Thermal Degradation Studies of Melamine

Polymer Dr. N. K. Patel EXPERIMENT 1 Aim

Polymer Dr. N. K. Patel EXPERIMENT: 5 PREPARATION OF MELAMINE FORMALDEHYDE RESIN Aim: To prepare melamine formaldehyde resin. Requirements: Melamine, formaline

PDF On Aug 6, 2003, A Pizzi and others published Melamine–Formaldehyde Adhesives . See all › 12 during resin preparation at which addition of a drop of MF reaction mixture to a test tube

Melamine Formaldehyde Powder Resin Melfores 103 P is a powder Melamine formaldehyde resin used for glazing of amino moulded Distilled or de‐ionized water is recommended for the preparation of resin solution. The dissolution would

Materials and Methods The preparation of the SMF resin 178 g of formaldehyde solution (37% wt %) and 1.3 g of borax (0.3 wt %) were put into a reactor.

The microcapsules used for electrophoretic display were prepared by in-situ polymerization. The core material contained electrophoretic particles (phthalocyanine blue and TiO2) and tetrachloroethylene (TCE), and the wall material were made of melamine-formaldehyde resin. The effects of preparation conditions, such as the concentration of

Melamine-urea-formaldehyde is a synthetic resin belonging to the amino resin family. Amino resins are thermosetting polymers made by combining an aldehyde with a compound containing an amino (-NH,) group (Amit Mukherjee & Subrata Ghosh, 1996).

Effect of emulsion preparation method on microencapsulation of n-octadecane using melamine-formaldehyde pre-polymers M The microcapsules containing n-octadecane as the core material and melamine-formaldehyde resin as the wall material have been synthesized by in situ polymerization method. A systematic study has been carried out to investigate the effect of the method used in the

Melamine / ˈ m ɛ l ə m iː n / is the organic compound with the formula C 3 H 6 N 6. This white solid is a trimer of cyanamide, with a 1,3,5-triazine skeleton.

13/06/1995 · A process of producing an aqueous solution of a sulfonated melamine-formaldehyde resin. The process comprises condensing melamine and formaldehyde or a precursor of formaldehyde (e.g. paraformaldehyde) in an aqueous mixture having a pH in the range of 8-10 to form a reaction mixture containing a condensation product of melamine and

3.3 Waste rubber powder preparation 25 3.4 Treatment of waste rubber powder 25 3.4.1 Treatment of waste rubber powder with 20% nitric acid 25-26 3.4.2 Treatment of waste rubber powder with 30% hydrogen peroxide 26 3.4.3 Treatment of waste rubber powder with acetone 26-27 3.5 Melamine urea formaldehyde based resin preparation 27 3.6 Optimization and formulation of melamine urea 27 …

Phenol–melamine–formaldehyde resins (PMF-resins) show, in some respects, better properties than the corresponding MF- and PF-condensates. 59, 69, 70 The preparation of these resins is described in various patents and publications. 71–81

Melamine resin or melamine formaldehyde (also shortened to melamine) is a hard, thermosetting plastic material made from melamine and formaldehyde by polymerization. [1] In its butylated form, it is dissolved in n -butanol and xylene .

A two-step organic sol–gel process for the preparation of monodispersed or narrow-dispersed melamine– formaldehyde (MF) resin polymer colloidal spheres in water was developed.

Phenol/formaldehyde resins and melamine/formaldehyde resins are standard resins used for many products. The choice of resin depends on the desired properties. The choice of resin depends on the

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation.

Preparation of Melamine-Formaldehyde Resin Microcapsules

UREA-FORMALDEHYDE ADHESIVE RESINS*

The resin used was a melamine-formaldehyde resin containing 3.3 moles of formaldehyde for each mole of melamine, prepared as described in the first paragraph of Example 1. Upon the addition of relatively small amounts of hydrochloric acid to the solution a precipitation of a white amorphous resin occurs, and this condition persists until a pHl of about 3.5 is obtained, corresponding to about 0

Melamine Formaldehyde Powder Resin Melfores 103 P is a powder Melamine formaldehyde resin used for glazing of amino moulded Distilled or de‐ionized water is recommended for the preparation of resin solution. The dissolution would

Melamine-formaldehyde resin was synthesized to be used with the synthesized hyperbranched resins, and it was successfully modified by all hyperbranched resins at a ratio of 3:1.

urea-formaldehyde resin shell and an epoxy resin adhesive. The effects of the key factors, i.e., The effects of the key factors, i.e., core–wall ratio, reaction temperature, pH and stirring rate, were investigated by characterizing

Polymer Dr. N. K. Patel EXPERIMENT: 5 PREPARATION OF MELAMINE FORMALDEHYDE RESIN Aim: To prepare melamine formaldehyde resin. Requirements: Melamine, formaline

Melamine formaldehyde (MF) foam is kind of fire-retardant material and has great potential in acoustic and thermal insulation area. In this article, MF resin foam was prepared by microwave radiation.

the laboratory with a formaldehyde/(urea melamine) mole ratio of 1.48. The physical characteristics of The physical characteristics of the MUF resin including nonvolatile solids, specific gravity, pH, free formaldehyde, and viscosity, etc., were

material safety data sheet MF415 Melamine Formaldehyde Resin Powder – [Distributed] Version No.:6 – Distribution date: 11/24/2009 possible carcinogenic to humans by inhalation.

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse Feng Fu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

Approximately 1 million metric tons of urea-formaldehyde resin are produced annually. More than 70% of this urea-formaldehyde resin is used by the forest products industry for a variety of purposes.

Preparation and Characterization of Melamine-Formaldehyde Resin Micro- and Nanocapsules Filled with n-Dodecane. Kongying Zhu School of Materials Science and Engineering, and Tianjin Key Laboratory of Composite and Functional Materials , Tianjin University , Tianjin , China , Hengzhi Qi School of Materials Science and Engineering, and Tianjin Key Laboratory of Composite and …

Phenol–melamine–formaldehyde resins (PMF-resins) show, in some respects, better properties than the corresponding MF- and PF-condensates. 59, 69, 70 The preparation of these resins is described in various patents and publications. 71–81

Previous article in issue: Simultaneous polymerization and formation of polyacetylene film on the surface of concentrated soluble Ziegler-type catalyst solution

Formaldehyde (MUF) resin is selected as the resin for wood adhesive production because of less costly and high water resistant compared to Melamine Formaldehyde (MF) and Urea Formaldehyde (UF) resins (Dunky, 2003).

The Polyurethane Foams Based on Melamine-formaldehyde

Preparation molecular weight determ ination formaldehyde

The same procedure was used for the preparation of the melamine formaldehyde resin (MF) with a mixture of 33 g K 2 CO 3, 21 g melamine and 20 ml formaldehyde. The resultant solid resins were cured for a week at room temperature and then placed in a vacuum oven for 24 h at 75 °C to ensure complete dryness, then powdered.

A melamine-formaldehyde resin consisting essentially of 2.0 to 2.5 mols of formaldehyde per mol of melamine and having a miscibility of one part by weight in 0.5 to 1.5 parts by weight of water at 25 C., and prepared by the process of claim 1.

Yan Jiang, Wanli Zhou, Mengjin Jiang, Pengqing Liu and Jianjun Xu, Flame retardant study of formalized polyvinyl alcohol fiber coated with melamine formaldehyde resins and the synergistic effect of copper ions, Polymer Degradation and Stability, 144, (331), (2017).

formaldehyde with melamine (1,3,5-triazine-2,4,6-triamine) [17]. These melamine-based resins have These melamine-based resins have found several applications, since melamine allows the obtaining of polymers with relatively high

13/06/1995 · A process of producing an aqueous solution of a sulfonated melamine-formaldehyde resin. The process comprises condensing melamine and formaldehyde or a precursor of formaldehyde (e.g. paraformaldehyde) in an aqueous mixture having a pH in the range of 8-10 to form a reaction mixture containing a condensation product of melamine and

A two-step organic sol–gel process for the preparation of monodispersed or narrow-dispersed melamine– formaldehyde (MF) resin polymer colloidal spheres in water was developed.

the laboratory with a formaldehyde/(urea melamine) mole ratio of 1.48. The physical characteristics of The physical characteristics of the MUF resin including nonvolatile solids, specific gravity, pH, free formaldehyde, and viscosity, etc., were

Comparative Study of Synthesis Procedures for Urea – Formaldehyde Resins (Part I) Mathew Obichukwu EDOGA 64 Keywords Urea-Formaldehyde resin, Synthesis- …

Melamine-modified urea formaldehyde resin for bonding particleboards Chung-Yun Hse Feng Fu Hui Pan Abstract For the development of a cost-effective melamine-modified urea formaldehyde resin (MUF), the study evaluated the effects

Melamine formaldehyde (MF) foam is a kind of fire-retardant material, which has many excellent properties. In this paper, the effect of foaming agent on foam-cell structure of MF foam was discussed, along with the compressive property, the water absorption and its thermo gravimetric behavior as well as its fire-retardant property behaved by

urea-formaldehyde resin shell and an epoxy resin adhesive. The effects of the key factors, i.e., The effects of the key factors, i.e., core–wall ratio, reaction temperature, pH and stirring rate, were investigated by characterizing

The preparation is based on an assembly process, with evaporation of an ethanol-water solution containing melamine formaldehyde resin (MF resin) as carbon source, nitrogen source, and chelating agent. Moreover, F127 and Co(NO) are used as template and metallic precursor, respectively.

Melamine formaldehyde microcapsules with fragrance core

Melamine and formaldehyde are used in the production of polymers, so-called melamine resins, which are used to manufacture kitchen dishes such as plates, cups or bowls as well as kitchen utensils such as cooking spoons or spatulas.

Ammeline–melamine–formaldehyde resins. Preparation and

The Decomposition Process of Melamine Formaldehyde Cores

Melamine-formaldehyde resin Britannica.com

The same procedure was used for the preparation of the melamine formaldehyde resin (MF) with a mixture of 33 g K 2 CO 3, 21 g melamine and 20 ml formaldehyde. The resultant solid resins were cured for a week at room temperature and then placed in a vacuum oven for 24 h at 75 °C to ensure complete dryness, then powdered.

Study of Preparation and Properties of Fire-Retardant

pH value during microencapsulation had to be lowered in a linear way or in smaller steps to 5.0 or lower. Keywords: thermal properties, microencapsulation, melamine-formaldehyde resin…

Preparation and characterization of microencapsulated LDHs