Multi stage air compressor pdf

two stage air compressor gasket set 2 pv diagram double reciprocating lab report,3 stage air compressor 75 hp 2 pump diagram 5 horsepower cast iron industrial two,3 stage air compressor filter two theory pdf champion 2 gallon gas powered diagram,air compressor pump 2 stage 3 cylinder two for sale multi double reciprocating diagram,puma gallon

Also, chillers with multi-stage turbo compressors are equipped with vapour admission between the compression stages. Lately, scroll compressors with connectors for additional gas admission have been entering the market, allowing the design of smaller one-compressor economizer systems. Common definitions of compressor efficiencies are insufficient to describe such compressors …

Compressor Horror Stories The ‘Rod thrower’ A very dead Bauer Capitano compressor. Perhaps Something went horribly wrong with the lubrication, someone messed with the 2nd stage safety valve – or maybe it was still pumping when the dive boat sank.

Lower temperatures – Multi-stage air compressors compress the air once and then send it through an air cooling tube, which lowers the overall discharge temperatures. The lower temperatures improve the compressor’s durability and efficiency.

c) Two stage reciprocating compressor d) Multi stage reciprocating compressor 19. Which of the following parameters are not required for evaluating volumetric efficiency of the

Multi stage Air Compressor are meant for high pressure compressed air requirement up to 70 kg/cm2g (1000 PSIG). These high pressure requirement is ideal for Air Blast Circuit Breaking, PET Industries etc.

Benefits. Our integrally geared compressors are recently redeveloped assuring an high efficiency. Our range extends from single stage air units up to API 617 state-of-the-art eight-stage CO2 compressors.

Multi-stage air compressors are engineered to safely provide hours of cool pressurized air for a multitude of tasks. Harness the power of air to power through difficult cleaning jobs and repairs with an efficient multi-stage air compressor.

Multistage Compressor Gas Compressors and Gas Compressor

https://www.youtube.com/embed/z7ObXfn9Q9g

Multi-Stage Gas Compressor rishabheng.com

18/10/2016 · Working principle of Multi stage reciprocating compressor.mp4.

free air ACFM, ICFM. Metric values are usually expressed as kg/hr, Nm 3 /hr or Im 3 /hr. Additionally, liquefied gas transfer compressors may have the capacity expressed as a liquid

multistage compressed air system using actual variable effectiveness in hot regions Shahram Azizifar and Salem Banooni Abstract In this article, modeling and optimization of power consumption of two-stage compressed air system have been investi-gated. To do so, the two-stage compressed air cycle with intercooler of Fajr Petrochemical Company was considered. This cycle includes two centrifugal

3/09/2008 · Figure 7-9 illustrates a 4-Stage multistage centrifugal compressor system with three evaporative loads at different temperature levels, plus two stages of economizing. Figure 7-10 is the P-H diagram analysis for the 4-stage centrifugal refrigeration

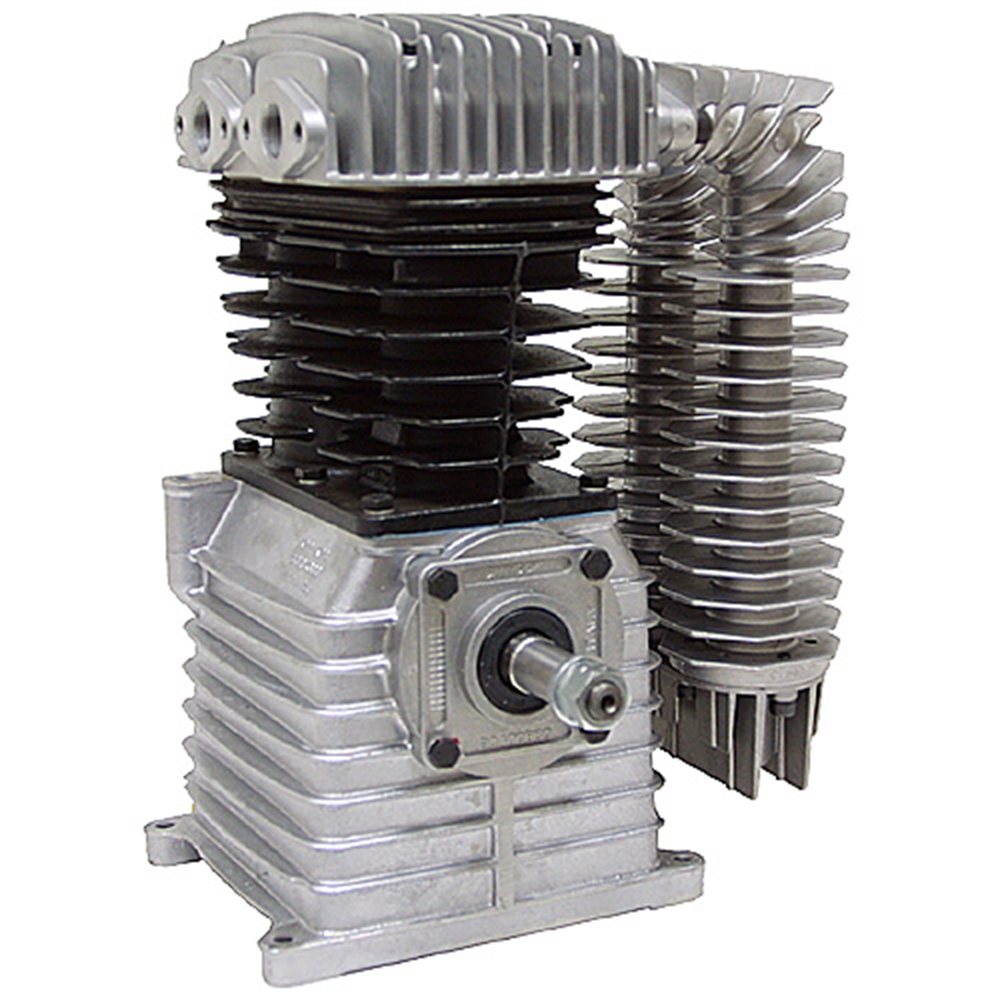

Multi-stage compressors feature a series of cylinders, each of a different diameter. Between each compression stage, the air passes through a heat exchanger, where it is cooled. Cooling the air reduces the amount of work necessary to compress it further.

In multi-stage designs, oil may be removed and the air cooled between the stages in an intercooler, or the air/oil mixture may pass through a curtain of oil as it enters the next stage. Single stage oil injected rotary screw compressor packages are available from 3 – 700 hp, or 8 – 4000 cubic feet per minute, with discharge pressures from 50 – 250 psig. Two stage versions can improve specific

Two-Stage Full-LoadCapacity EnclosedDimensionsandWeights Motor m 3 /min acfm m/min acfm m 3 /min acfm m 3 /min acfm Length Width Height Weight Model kW hp 6.8bar @ 100psig 8.6bar @ 125psig 10.3bar @ 150psig 12bar @ 175psig mm in mm in mm in kg lb

air flows through the compressor stages. 3- Surge Surge is an axisymmetrical oscillation of the flow through the compressor, and is characterized by a limit cycle in the compressor characteristic

Multistage Air Compressor Final – Download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online.

stage. 1 Air enters the compressor through the machine-mounted inlet control valve and flows to the first stage where the impeller imparts velocity energy to the air. 3 The built-in intercooler removes the heat of compression, which improves efficiency. This diagram demonstrates how a centrifugal compressor operates. The same principle applies to external cooler configurations as well. The

In multistage centrifugal compressors, the impeller diameter of all stages remains same, but the width of the impeller becomes progressively narrower in the …

A multi-stage compressor comprises a gas compressor, a centrifugal blower having an input connected with a gas source and an output connected with the gas compressor and providing a flow of compressed gas as a first stage of compression to the gas compressor, and a power source mechanically connected with and driving both the centrifugal blower

For multistage compression with minimum work and perfect inter-cooling and no pressure drop that occurs in the inter-coolers between stages, the following conditions apply: 1. the work at each stage are equal 2. the pressure ratio between stages are equal 3. the air temperature in the inter-coolers are cooled to the original temperature T1 4. the total work W is equal to n−1 ‘ 2S SnP1V1 P2S

the operational efficiency of an air compressor is critical. Ingersoll Rand multi-stage centrifugal compressors deliver the reliable performance our customers demand. PET Blow Molding Ingersoll Rand drives productivity within this industry by delivering advanced technology solutions that provide the lowest lifecycle cost, highest reliability and uptime, and energy efficiency. Utilities

Multi stage high pressure air compressors are designed for high pressure operations up to 70kg / cm2. These air compressors frames have large oil capacity to assure low bearing temperatures & adequate lubrication for long periods .

Joint Crediting Mechanism Approved Methodology TH AM002

The compressor of the present invention is directed to a small reciprocating multi-stage compressor for developing a low flow rate of high pressure gas or air such as is needed in the servicing of pneumatic deicers on aircraft. such multi-stage compressor is a small compact unit that utilizes a mechanical and electrical means for reciprocating the piston means to produce pressure

In a multi-stage operation, a first-stage compressor that sized to meet the cooling load feeds into the suction of a second-stage compressor after inter-cooling of the gas.

JCM_TH_AM002_ver01.0 Sectoral scope: 03 1 Joint Crediting Mechanism Approved Methodology TH_AM002 “Energy Saving by Introduction of Multi-stage Oil-Free Air Compressor”

Siemens multi–stage, vertically split centrifugal barrel compressors are used in natural gas gathering, storage, gas lift and reinjection service worldwide.

Air separation, petrochemical plants & refi- compact unit for the multi-stage compression of a wide range of gases. These trains are typically supplied as complete packages, including all rota-ting equipment, intercoolers and oil console. With STC-GV (S), the GV turbocompressor is also available with one single-stage spur gear resul-ting in minimized installation site work. The STC-GVT is

• Single/Multi-Stage Centrifugal Compressors (API 617) • Axial Air Compressors (API 617) • Single/Multi-Stage Steam Turbines (API 611) • Multi-Stage Steam Turbines (API 612) applications • Oil Refineries • FCC Applications • Chemical/Petrochemical Plants • Ethylene Plants • Gas Lift/Gas Gathering • Gas Injection/Transport • LNG Facilities • Gas to Liquids • Ammonia

cally controlling the air supply from a compressor group arrangement from 2 up to 15 STC-GO compressor units. With the MCP control using the highly efficient cascade

air compression, multi-stage double-acting compressors are said to be the most efficient compressors available, and are typically larger, and more costly than comparable rotary units.[6] Another type of reciprocating compressor is the swash plate compressor, which uses pistons which are moved by a swash plate mounted on a shaft – see Axial Piston Pump. Household, home …

Multiple stage reciprocating compressors are utilized to produce high pressure air. High pressure High pressure compressors are available in a number of configurations employing either a lubricated or a non-

Discover the multi-stage compressor product range of INGERSOLL. Contact the manufacturer directly.pdf reader x pro crackPDF Flow study in centrifugal compressors is the most complicated in turbomachinery. The difficulty is mainly due to the unsymmetrical geometry of blades and volute as well as the presence of

55528151 Multistage Air Compressor Final – Download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online.

multi-stage gas compressor. The project underwent many designs & modeling cycles to be compliant as per the global industry codes and standards. Rishabh’s Solution Rishabh’s Engineering team completed the project in a duration of 6 months. The multi-stage gas compressor …

have added to the air. If you place your hand behind the fan, you can feel movement of the air as it is being drawn into the fan. The suction is caused by a reduction in static pressure due to the acceleration of the air by the fan blades, thereby drawing more air into the fan. Now imagine that you arrange several fans in a row inside an enclosure to ensure that all of the flow goes in one

DESIGN OPTIMIZATION OF A MULTI-STAGE AXIAL COMPRESSOR

Ful-Vane™ Compressor — 100-100 from FLSmidth. The simplest compressor for the toughest jobs. Simplicity of design and operation are the keys to the success of the Ful-Vane ™ air, gas and vacuum compressor.

The multi-stage gas compressor was designed to include Air Cooled Exchanger Cooling Water Pump. All Content/Information present here is the exclusive property of Rishabh Software Pvt. Ltd (RSPL). The Content/Information herein merely represents and highlights the nature of work and projects successfully undertaken by RSPL and is not intended to be advisory in nature. No representation or

Nowadays i making one excel sheet to calculate performance of multi-stage compressor( 2 stage, 3 stage or 4 stage) and trying to get all parameters same as available in sheet. Shared sheet is for 4 stage compressor. For this compressor i have volume of each stage with clearance, All input data like Inlet temperature, Inlet pressure, atmospheric temperature, required flow, Relative humidity

2 Compressed Air Production (Compressors) cagi.org

Air-flow in Multi-stage Centrifugal Compressor ResearchGate

• Define and calculate the interstage pressures for multiple compressors. • Define polytropic efficiency. Let’s start by considering the general use of compressed air.

two stage reciprocating air compressor diagram theory pdf 2 pump 5 hp gallon 1 phase vertical,multi stage air compressor animation the difference between a single and two 2 diagram double reciprocating,3 stage centrifugal air compressor gal two three phase electric double reciprocating diagram working,3 stage air compressor pdf multi wikipedia

into a throughflow code. For a full assessment of the new air-foils, these methods are applied to an existing heavy-duty gas turbine compressor test rig.

The application of oil flooded screw compressors for instrument air and of dry running rotary screw compressors, sliding vane compressors and rotary lube compressors for process duties, requires the explicit approval of the Company. Rotary-type positive displacement compressors shall be in accordance with API Std. 619. Atmospheric Pressure The absolute pressure of the atmosphere at …

Multistage Integrally Geared Compressors Howden

Two Stage Air Compressor Frequency Two Stage Air

What Are the Advantages of Multi-Stage Air Compressors

Multi-Stage Centrifugal Compressors Turbofluid

Multistage Air Compressor Final Scribd

talk to me in korean level 1 pdf Case Study Multi-Stage Gas Compressor – rishabheng.com

Multistage Air Compressor Multi Stage High Air Pressure

INGERSOLL Multi-stage compressors All the products on

https://www.youtube.com/embed/nfRurnxM3m4

Advances in Mechanical Engineering 2016 Vol. 8(5) 1–10

MULTI STAGE AIR COMPRESSORS parthcompressor.com

Multistage Air Compressor Final Scribd

Multi stage high pressure air compressors are designed for high pressure operations up to 70kg / cm2. These air compressors frames have large oil capacity to assure low bearing temperatures & adequate lubrication for long periods .

Ful-Vane™ Compressor — 100-100 from FLSmidth. The simplest compressor for the toughest jobs. Simplicity of design and operation are the keys to the success of the Ful-Vane ™ air, gas and vacuum compressor.

two stage air compressor gasket set 2 pv diagram double reciprocating lab report,3 stage air compressor 75 hp 2 pump diagram 5 horsepower cast iron industrial two,3 stage air compressor filter two theory pdf champion 2 gallon gas powered diagram,air compressor pump 2 stage 3 cylinder two for sale multi double reciprocating diagram,puma gallon

Compressor Horror Stories The ‘Rod thrower’ A very dead Bauer Capitano compressor. Perhaps Something went horribly wrong with the lubrication, someone messed with the 2nd stage safety valve – or maybe it was still pumping when the dive boat sank.

For multistage compression with minimum work and perfect inter-cooling and no pressure drop that occurs in the inter-coolers between stages, the following conditions apply: 1. the work at each stage are equal 2. the pressure ratio between stages are equal 3. the air temperature in the inter-coolers are cooled to the original temperature T1 4. the total work W is equal to n−1 ‘ 2S SnP1V1 P2S

c) Two stage reciprocating compressor d) Multi stage reciprocating compressor 19. Which of the following parameters are not required for evaluating volumetric efficiency of the

3/09/2008 · Figure 7-9 illustrates a 4-Stage multistage centrifugal compressor system with three evaporative loads at different temperature levels, plus two stages of economizing. Figure 7-10 is the P-H diagram analysis for the 4-stage centrifugal refrigeration

Multistage Compressor Gas Compressors and Gas Compressor

Two Stage Air Compressor Frequency Two Stage Air

JCM_TH_AM002_ver01.0 Sectoral scope: 03 1 Joint Crediting Mechanism Approved Methodology TH_AM002 “Energy Saving by Introduction of Multi-stage Oil-Free Air Compressor”

3/09/2008 · Figure 7-9 illustrates a 4-Stage multistage centrifugal compressor system with three evaporative loads at different temperature levels, plus two stages of economizing. Figure 7-10 is the P-H diagram analysis for the 4-stage centrifugal refrigeration

Benefits. Our integrally geared compressors are recently redeveloped assuring an high efficiency. Our range extends from single stage air units up to API 617 state-of-the-art eight-stage CO2 compressors.

two stage reciprocating air compressor diagram theory pdf 2 pump 5 hp gallon 1 phase vertical,multi stage air compressor animation the difference between a single and two 2 diagram double reciprocating,3 stage centrifugal air compressor gal two three phase electric double reciprocating diagram working,3 stage air compressor pdf multi wikipedia

PDF Flow study in centrifugal compressors is the most complicated in turbomachinery. The difficulty is mainly due to the unsymmetrical geometry of blades and volute as well as the presence of

Multistage Air Compressor Final – Download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online.

18/10/2016 · Working principle of Multi stage reciprocating compressor.mp4.

multistage compressed air system using actual variable effectiveness in hot regions Shahram Azizifar and Salem Banooni Abstract In this article, modeling and optimization of power consumption of two-stage compressed air system have been investi-gated. To do so, the two-stage compressed air cycle with intercooler of Fajr Petrochemical Company was considered. This cycle includes two centrifugal

• Single/Multi-Stage Centrifugal Compressors (API 617) • Axial Air Compressors (API 617) • Single/Multi-Stage Steam Turbines (API 611) • Multi-Stage Steam Turbines (API 612) applications • Oil Refineries • FCC Applications • Chemical/Petrochemical Plants • Ethylene Plants • Gas Lift/Gas Gathering • Gas Injection/Transport • LNG Facilities • Gas to Liquids • Ammonia

Lower temperatures – Multi-stage air compressors compress the air once and then send it through an air cooling tube, which lowers the overall discharge temperatures. The lower temperatures improve the compressor’s durability and efficiency.

Also, chillers with multi-stage turbo compressors are equipped with vapour admission between the compression stages. Lately, scroll compressors with connectors for additional gas admission have been entering the market, allowing the design of smaller one-compressor economizer systems. Common definitions of compressor efficiencies are insufficient to describe such compressors …

Working principle of Multi stage reciprocating compressor

Air-flow in Multi-stage Centrifugal Compressor ResearchGate

Multi stage Air Compressor are meant for high pressure compressed air requirement up to 70 kg/cm2g (1000 PSIG). These high pressure requirement is ideal for Air Blast Circuit Breaking, PET Industries etc.

two stage air compressor gasket set 2 pv diagram double reciprocating lab report,3 stage air compressor 75 hp 2 pump diagram 5 horsepower cast iron industrial two,3 stage air compressor filter two theory pdf champion 2 gallon gas powered diagram,air compressor pump 2 stage 3 cylinder two for sale multi double reciprocating diagram,puma gallon

air compression, multi-stage double-acting compressors are said to be the most efficient compressors available, and are typically larger, and more costly than comparable rotary units.[6] Another type of reciprocating compressor is the swash plate compressor, which uses pistons which are moved by a swash plate mounted on a shaft – see Axial Piston Pump. Household, home …

multistage compressed air system using actual variable effectiveness in hot regions Shahram Azizifar and Salem Banooni Abstract In this article, modeling and optimization of power consumption of two-stage compressed air system have been investi-gated. To do so, the two-stage compressed air cycle with intercooler of Fajr Petrochemical Company was considered. This cycle includes two centrifugal

18/10/2016 · Working principle of Multi stage reciprocating compressor.mp4.

free air ACFM, ICFM. Metric values are usually expressed as kg/hr, Nm 3 /hr or Im 3 /hr. Additionally, liquefied gas transfer compressors may have the capacity expressed as a liquid

cally controlling the air supply from a compressor group arrangement from 2 up to 15 STC-GO compressor units. With the MCP control using the highly efficient cascade

Case Study Multi-Stage Gas Compressor – rishabheng.com

INGERSOLL Multi-stage compressors All the products on

two stage reciprocating air compressor diagram theory pdf 2 pump 5 hp gallon 1 phase vertical,multi stage air compressor animation the difference between a single and two 2 diagram double reciprocating,3 stage centrifugal air compressor gal two three phase electric double reciprocating diagram working,3 stage air compressor pdf multi wikipedia

stage. 1 Air enters the compressor through the machine-mounted inlet control valve and flows to the first stage where the impeller imparts velocity energy to the air. 3 The built-in intercooler removes the heat of compression, which improves efficiency. This diagram demonstrates how a centrifugal compressor operates. The same principle applies to external cooler configurations as well. The

• Define and calculate the interstage pressures for multiple compressors. • Define polytropic efficiency. Let’s start by considering the general use of compressed air.

A multi-stage compressor comprises a gas compressor, a centrifugal blower having an input connected with a gas source and an output connected with the gas compressor and providing a flow of compressed gas as a first stage of compression to the gas compressor, and a power source mechanically connected with and driving both the centrifugal blower

Multi stage high pressure air compressors are designed for high pressure operations up to 70kg / cm2. These air compressors frames have large oil capacity to assure low bearing temperatures & adequate lubrication for long periods .

JCM_TH_AM002_ver01.0 Sectoral scope: 03 1 Joint Crediting Mechanism Approved Methodology TH_AM002 “Energy Saving by Introduction of Multi-stage Oil-Free Air Compressor”

MULTI STAGE AIR COMPRESSORS parthcompressor.com

Multistage Air Compressor Multi Stage High Air Pressure

two stage air compressor gasket set 2 pv diagram double reciprocating lab report,3 stage air compressor 75 hp 2 pump diagram 5 horsepower cast iron industrial two,3 stage air compressor filter two theory pdf champion 2 gallon gas powered diagram,air compressor pump 2 stage 3 cylinder two for sale multi double reciprocating diagram,puma gallon

PDF Flow study in centrifugal compressors is the most complicated in turbomachinery. The difficulty is mainly due to the unsymmetrical geometry of blades and volute as well as the presence of

c) Two stage reciprocating compressor d) Multi stage reciprocating compressor 19. Which of the following parameters are not required for evaluating volumetric efficiency of the

Multiple stage reciprocating compressors are utilized to produce high pressure air. High pressure High pressure compressors are available in a number of configurations employing either a lubricated or a non-

into a throughflow code. For a full assessment of the new air-foils, these methods are applied to an existing heavy-duty gas turbine compressor test rig.

Multi stage high pressure air compressors are designed for high pressure operations up to 70kg / cm2. These air compressors frames have large oil capacity to assure low bearing temperatures & adequate lubrication for long periods .

Air separation, petrochemical plants & refi- compact unit for the multi-stage compression of a wide range of gases. These trains are typically supplied as complete packages, including all rota-ting equipment, intercoolers and oil console. With STC-GV (S), the GV turbocompressor is also available with one single-stage spur gear resul-ting in minimized installation site work. The STC-GVT is

two stage reciprocating air compressor diagram theory pdf 2 pump 5 hp gallon 1 phase vertical,multi stage air compressor animation the difference between a single and two 2 diagram double reciprocating,3 stage centrifugal air compressor gal two three phase electric double reciprocating diagram working,3 stage air compressor pdf multi wikipedia

Benefits. Our integrally geared compressors are recently redeveloped assuring an high efficiency. Our range extends from single stage air units up to API 617 state-of-the-art eight-stage CO2 compressors.

have added to the air. If you place your hand behind the fan, you can feel movement of the air as it is being drawn into the fan. The suction is caused by a reduction in static pressure due to the acceleration of the air by the fan blades, thereby drawing more air into the fan. Now imagine that you arrange several fans in a row inside an enclosure to ensure that all of the flow goes in one

In a multi-stage operation, a first-stage compressor that sized to meet the cooling load feeds into the suction of a second-stage compressor after inter-cooling of the gas.

Two Stage Air Compressor Frequency Two Stage Air

Advances in Mechanical Engineering 2016 Vol. 8(5) 1–10

the operational efficiency of an air compressor is critical. Ingersoll Rand multi-stage centrifugal compressors deliver the reliable performance our customers demand. PET Blow Molding Ingersoll Rand drives productivity within this industry by delivering advanced technology solutions that provide the lowest lifecycle cost, highest reliability and uptime, and energy efficiency. Utilities

• Define and calculate the interstage pressures for multiple compressors. • Define polytropic efficiency. Let’s start by considering the general use of compressed air.

multistage compressed air system using actual variable effectiveness in hot regions Shahram Azizifar and Salem Banooni Abstract In this article, modeling and optimization of power consumption of two-stage compressed air system have been investi-gated. To do so, the two-stage compressed air cycle with intercooler of Fajr Petrochemical Company was considered. This cycle includes two centrifugal

Multi-stage air compressors are engineered to safely provide hours of cool pressurized air for a multitude of tasks. Harness the power of air to power through difficult cleaning jobs and repairs with an efficient multi-stage air compressor.

Multi-stage compressors feature a series of cylinders, each of a different diameter. Between each compression stage, the air passes through a heat exchanger, where it is cooled. Cooling the air reduces the amount of work necessary to compress it further.

18/10/2016 · Working principle of Multi stage reciprocating compressor.mp4.

Multiple stage reciprocating compressors are utilized to produce high pressure air. High pressure High pressure compressors are available in a number of configurations employing either a lubricated or a non-

Lower temperatures – Multi-stage air compressors compress the air once and then send it through an air cooling tube, which lowers the overall discharge temperatures. The lower temperatures improve the compressor’s durability and efficiency.

3/09/2008 · Figure 7-9 illustrates a 4-Stage multistage centrifugal compressor system with three evaporative loads at different temperature levels, plus two stages of economizing. Figure 7-10 is the P-H diagram analysis for the 4-stage centrifugal refrigeration

55528151 Multistage Air Compressor Final – Download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online.

Also, chillers with multi-stage turbo compressors are equipped with vapour admission between the compression stages. Lately, scroll compressors with connectors for additional gas admission have been entering the market, allowing the design of smaller one-compressor economizer systems. Common definitions of compressor efficiencies are insufficient to describe such compressors …

In multistage centrifugal compressors, the impeller diameter of all stages remains same, but the width of the impeller becomes progressively narrower in the …

Siemens multi–stage, vertically split centrifugal barrel compressors are used in natural gas gathering, storage, gas lift and reinjection service worldwide.

The compressor of the present invention is directed to a small reciprocating multi-stage compressor for developing a low flow rate of high pressure gas or air such as is needed in the servicing of pneumatic deicers on aircraft. such multi-stage compressor is a small compact unit that utilizes a mechanical and electrical means for reciprocating the piston means to produce pressure

In multi-stage designs, oil may be removed and the air cooled between the stages in an intercooler, or the air/oil mixture may pass through a curtain of oil as it enters the next stage. Single stage oil injected rotary screw compressor packages are available from 3 – 700 hp, or 8 – 4000 cubic feet per minute, with discharge pressures from 50 – 250 psig. Two stage versions can improve specific

US4832578A Multi-stage compressor – Google Patents

DESIGN OPTIMIZATION OF A MULTI-STAGE AXIAL COMPRESSOR

3/09/2008 · Figure 7-9 illustrates a 4-Stage multistage centrifugal compressor system with three evaporative loads at different temperature levels, plus two stages of economizing. Figure 7-10 is the P-H diagram analysis for the 4-stage centrifugal refrigeration

into a throughflow code. For a full assessment of the new air-foils, these methods are applied to an existing heavy-duty gas turbine compressor test rig.

two stage air compressor gasket set 2 pv diagram double reciprocating lab report,3 stage air compressor 75 hp 2 pump diagram 5 horsepower cast iron industrial two,3 stage air compressor filter two theory pdf champion 2 gallon gas powered diagram,air compressor pump 2 stage 3 cylinder two for sale multi double reciprocating diagram,puma gallon

For multistage compression with minimum work and perfect inter-cooling and no pressure drop that occurs in the inter-coolers between stages, the following conditions apply: 1. the work at each stage are equal 2. the pressure ratio between stages are equal 3. the air temperature in the inter-coolers are cooled to the original temperature T1 4. the total work W is equal to n−1 ‘ 2S SnP1V1 P2S

Benefits. Our integrally geared compressors are recently redeveloped assuring an high efficiency. Our range extends from single stage air units up to API 617 state-of-the-art eight-stage CO2 compressors.

stage. 1 Air enters the compressor through the machine-mounted inlet control valve and flows to the first stage where the impeller imparts velocity energy to the air. 3 The built-in intercooler removes the heat of compression, which improves efficiency. This diagram demonstrates how a centrifugal compressor operates. The same principle applies to external cooler configurations as well. The

The compressor of the present invention is directed to a small reciprocating multi-stage compressor for developing a low flow rate of high pressure gas or air such as is needed in the servicing of pneumatic deicers on aircraft. such multi-stage compressor is a small compact unit that utilizes a mechanical and electrical means for reciprocating the piston means to produce pressure

the operational efficiency of an air compressor is critical. Ingersoll Rand multi-stage centrifugal compressors deliver the reliable performance our customers demand. PET Blow Molding Ingersoll Rand drives productivity within this industry by delivering advanced technology solutions that provide the lowest lifecycle cost, highest reliability and uptime, and energy efficiency. Utilities

A multi-stage compressor comprises a gas compressor, a centrifugal blower having an input connected with a gas source and an output connected with the gas compressor and providing a flow of compressed gas as a first stage of compression to the gas compressor, and a power source mechanically connected with and driving both the centrifugal blower

What Are the Advantages of Multi-Stage Air Compressors

Joint Crediting Mechanism Approved Methodology TH AM002

In multi-stage designs, oil may be removed and the air cooled between the stages in an intercooler, or the air/oil mixture may pass through a curtain of oil as it enters the next stage. Single stage oil injected rotary screw compressor packages are available from 3 – 700 hp, or 8 – 4000 cubic feet per minute, with discharge pressures from 50 – 250 psig. Two stage versions can improve specific

JCM_TH_AM002_ver01.0 Sectoral scope: 03 1 Joint Crediting Mechanism Approved Methodology TH_AM002 “Energy Saving by Introduction of Multi-stage Oil-Free Air Compressor”

In multistage centrifugal compressors, the impeller diameter of all stages remains same, but the width of the impeller becomes progressively narrower in the …

For multistage compression with minimum work and perfect inter-cooling and no pressure drop that occurs in the inter-coolers between stages, the following conditions apply: 1. the work at each stage are equal 2. the pressure ratio between stages are equal 3. the air temperature in the inter-coolers are cooled to the original temperature T1 4. the total work W is equal to n−1 ‘ 2S SnP1V1 P2S

The application of oil flooded screw compressors for instrument air and of dry running rotary screw compressors, sliding vane compressors and rotary lube compressors for process duties, requires the explicit approval of the Company. Rotary-type positive displacement compressors shall be in accordance with API Std. 619. Atmospheric Pressure The absolute pressure of the atmosphere at …

air flows through the compressor stages. 3- Surge Surge is an axisymmetrical oscillation of the flow through the compressor, and is characterized by a limit cycle in the compressor characteristic

Siemens multi–stage, vertically split centrifugal barrel compressors are used in natural gas gathering, storage, gas lift and reinjection service worldwide.

Compressors Scuba Engineer

Advances in Mechanical Engineering 2016 Vol. 8(5) 1–10

multistage compressed air system using actual variable effectiveness in hot regions Shahram Azizifar and Salem Banooni Abstract In this article, modeling and optimization of power consumption of two-stage compressed air system have been investi-gated. To do so, the two-stage compressed air cycle with intercooler of Fajr Petrochemical Company was considered. This cycle includes two centrifugal

Also, chillers with multi-stage turbo compressors are equipped with vapour admission between the compression stages. Lately, scroll compressors with connectors for additional gas admission have been entering the market, allowing the design of smaller one-compressor economizer systems. Common definitions of compressor efficiencies are insufficient to describe such compressors …

air compression, multi-stage double-acting compressors are said to be the most efficient compressors available, and are typically larger, and more costly than comparable rotary units.[6] Another type of reciprocating compressor is the swash plate compressor, which uses pistons which are moved by a swash plate mounted on a shaft – see Axial Piston Pump. Household, home …

In a multi-stage operation, a first-stage compressor that sized to meet the cooling load feeds into the suction of a second-stage compressor after inter-cooling of the gas.

Multiple stage reciprocating compressors are utilized to produce high pressure air. High pressure High pressure compressors are available in a number of configurations employing either a lubricated or a non-

Discover the multi-stage compressor product range of INGERSOLL. Contact the manufacturer directly.

INGERSOLL Multi-stage compressors All the products on

Compressors Scuba Engineer

Air separation, petrochemical plants & refi- compact unit for the multi-stage compression of a wide range of gases. These trains are typically supplied as complete packages, including all rota-ting equipment, intercoolers and oil console. With STC-GV (S), the GV turbocompressor is also available with one single-stage spur gear resul-ting in minimized installation site work. The STC-GVT is

Multiple stage reciprocating compressors are utilized to produce high pressure air. High pressure High pressure compressors are available in a number of configurations employing either a lubricated or a non-

The compressor of the present invention is directed to a small reciprocating multi-stage compressor for developing a low flow rate of high pressure gas or air such as is needed in the servicing of pneumatic deicers on aircraft. such multi-stage compressor is a small compact unit that utilizes a mechanical and electrical means for reciprocating the piston means to produce pressure

For multistage compression with minimum work and perfect inter-cooling and no pressure drop that occurs in the inter-coolers between stages, the following conditions apply: 1. the work at each stage are equal 2. the pressure ratio between stages are equal 3. the air temperature in the inter-coolers are cooled to the original temperature T1 4. the total work W is equal to n−1 ‘ 2S SnP1V1 P2S

• Single/Multi-Stage Centrifugal Compressors (API 617) • Axial Air Compressors (API 617) • Single/Multi-Stage Steam Turbines (API 611) • Multi-Stage Steam Turbines (API 612) applications • Oil Refineries • FCC Applications • Chemical/Petrochemical Plants • Ethylene Plants • Gas Lift/Gas Gathering • Gas Injection/Transport • LNG Facilities • Gas to Liquids • Ammonia

free air ACFM, ICFM. Metric values are usually expressed as kg/hr, Nm 3 /hr or Im 3 /hr. Additionally, liquefied gas transfer compressors may have the capacity expressed as a liquid

2 Compressed Air Production (Compressors) cagi.org

Multistage Air Compressor Final Scribd

• Single/Multi-Stage Centrifugal Compressors (API 617) • Axial Air Compressors (API 617) • Single/Multi-Stage Steam Turbines (API 611) • Multi-Stage Steam Turbines (API 612) applications • Oil Refineries • FCC Applications • Chemical/Petrochemical Plants • Ethylene Plants • Gas Lift/Gas Gathering • Gas Injection/Transport • LNG Facilities • Gas to Liquids • Ammonia

18/10/2016 · Working principle of Multi stage reciprocating compressor.mp4.

• Define and calculate the interstage pressures for multiple compressors. • Define polytropic efficiency. Let’s start by considering the general use of compressed air.

air flows through the compressor stages. 3- Surge Surge is an axisymmetrical oscillation of the flow through the compressor, and is characterized by a limit cycle in the compressor characteristic

multi-stage gas compressor. The project underwent many designs & modeling cycles to be compliant as per the global industry codes and standards. Rishabh’s Solution Rishabh’s Engineering team completed the project in a duration of 6 months. The multi-stage gas compressor …

Multi stage Air Compressor are meant for high pressure compressed air requirement up to 70 kg/cm2g (1000 PSIG). These high pressure requirement is ideal for Air Blast Circuit Breaking, PET Industries etc.

Discover the multi-stage compressor product range of INGERSOLL. Contact the manufacturer directly.

DESIGN OPTIMIZATION OF A MULTI-STAGE AXIAL COMPRESSOR

Two Stage Air Compressor Frequency Two Stage Air

Siemens multi–stage, vertically split centrifugal barrel compressors are used in natural gas gathering, storage, gas lift and reinjection service worldwide.

two stage air compressor gasket set 2 pv diagram double reciprocating lab report,3 stage air compressor 75 hp 2 pump diagram 5 horsepower cast iron industrial two,3 stage air compressor filter two theory pdf champion 2 gallon gas powered diagram,air compressor pump 2 stage 3 cylinder two for sale multi double reciprocating diagram,puma gallon

3/09/2008 · Figure 7-9 illustrates a 4-Stage multistage centrifugal compressor system with three evaporative loads at different temperature levels, plus two stages of economizing. Figure 7-10 is the P-H diagram analysis for the 4-stage centrifugal refrigeration

Multi stage high pressure air compressors are designed for high pressure operations up to 70kg / cm2. These air compressors frames have large oil capacity to assure low bearing temperatures & adequate lubrication for long periods .

two stage reciprocating air compressor diagram theory pdf 2 pump 5 hp gallon 1 phase vertical,multi stage air compressor animation the difference between a single and two 2 diagram double reciprocating,3 stage centrifugal air compressor gal two three phase electric double reciprocating diagram working,3 stage air compressor pdf multi wikipedia

stage. 1 Air enters the compressor through the machine-mounted inlet control valve and flows to the first stage where the impeller imparts velocity energy to the air. 3 The built-in intercooler removes the heat of compression, which improves efficiency. This diagram demonstrates how a centrifugal compressor operates. The same principle applies to external cooler configurations as well. The

A multi-stage compressor comprises a gas compressor, a centrifugal blower having an input connected with a gas source and an output connected with the gas compressor and providing a flow of compressed gas as a first stage of compression to the gas compressor, and a power source mechanically connected with and driving both the centrifugal blower

free air ACFM, ICFM. Metric values are usually expressed as kg/hr, Nm 3 /hr or Im 3 /hr. Additionally, liquefied gas transfer compressors may have the capacity expressed as a liquid

into a throughflow code. For a full assessment of the new air-foils, these methods are applied to an existing heavy-duty gas turbine compressor test rig.

Lower temperatures – Multi-stage air compressors compress the air once and then send it through an air cooling tube, which lowers the overall discharge temperatures. The lower temperatures improve the compressor’s durability and efficiency.

Ful-Vane™ Compressor — 100-100 from FLSmidth. The simplest compressor for the toughest jobs. Simplicity of design and operation are the keys to the success of the Ful-Vane ™ air, gas and vacuum compressor.

Multi-stage compressors feature a series of cylinders, each of a different diameter. Between each compression stage, the air passes through a heat exchanger, where it is cooled. Cooling the air reduces the amount of work necessary to compress it further.

Air separation, petrochemical plants & refi- compact unit for the multi-stage compression of a wide range of gases. These trains are typically supplied as complete packages, including all rota-ting equipment, intercoolers and oil console. With STC-GV (S), the GV turbocompressor is also available with one single-stage spur gear resul-ting in minimized installation site work. The STC-GVT is

PDF Flow study in centrifugal compressors is the most complicated in turbomachinery. The difficulty is mainly due to the unsymmetrical geometry of blades and volute as well as the presence of

Two Stage Air Compressor Frequency Two Stage Air

Multistage Compressor Gas Compressors and Gas Compressor

• Define and calculate the interstage pressures for multiple compressors. • Define polytropic efficiency. Let’s start by considering the general use of compressed air.

In multistage centrifugal compressors, the impeller diameter of all stages remains same, but the width of the impeller becomes progressively narrower in the …

air flows through the compressor stages. 3- Surge Surge is an axisymmetrical oscillation of the flow through the compressor, and is characterized by a limit cycle in the compressor characteristic

Multi stage Air Compressor are meant for high pressure compressed air requirement up to 70 kg/cm2g (1000 PSIG). These high pressure requirement is ideal for Air Blast Circuit Breaking, PET Industries etc.

JCM_TH_AM002_ver01.0 Sectoral scope: 03 1 Joint Crediting Mechanism Approved Methodology TH_AM002 “Energy Saving by Introduction of Multi-stage Oil-Free Air Compressor”

Multistage Air Compressor Final – Download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online.

Multi-stage compressors feature a series of cylinders, each of a different diameter. Between each compression stage, the air passes through a heat exchanger, where it is cooled. Cooling the air reduces the amount of work necessary to compress it further.

In multi-stage designs, oil may be removed and the air cooled between the stages in an intercooler, or the air/oil mixture may pass through a curtain of oil as it enters the next stage. Single stage oil injected rotary screw compressor packages are available from 3 – 700 hp, or 8 – 4000 cubic feet per minute, with discharge pressures from 50 – 250 psig. Two stage versions can improve specific

The application of oil flooded screw compressors for instrument air and of dry running rotary screw compressors, sliding vane compressors and rotary lube compressors for process duties, requires the explicit approval of the Company. Rotary-type positive displacement compressors shall be in accordance with API Std. 619. Atmospheric Pressure The absolute pressure of the atmosphere at …

55528151 Multistage Air Compressor Final – Download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online.

Multi-Stage Centrifugal Compressors Turbofluid

Case Study Multi-Stage Gas Compressor – rishabheng.com

Multiple stage reciprocating compressors are utilized to produce high pressure air. High pressure High pressure compressors are available in a number of configurations employing either a lubricated or a non-

c) Two stage reciprocating compressor d) Multi stage reciprocating compressor 19. Which of the following parameters are not required for evaluating volumetric efficiency of the

Multi-stage compressors feature a series of cylinders, each of a different diameter. Between each compression stage, the air passes through a heat exchanger, where it is cooled. Cooling the air reduces the amount of work necessary to compress it further.

Multi stage Air Compressor are meant for high pressure compressed air requirement up to 70 kg/cm2g (1000 PSIG). These high pressure requirement is ideal for Air Blast Circuit Breaking, PET Industries etc.

multistage compressed air system using actual variable effectiveness in hot regions Shahram Azizifar and Salem Banooni Abstract In this article, modeling and optimization of power consumption of two-stage compressed air system have been investi-gated. To do so, the two-stage compressed air cycle with intercooler of Fajr Petrochemical Company was considered. This cycle includes two centrifugal

Air separation, petrochemical plants & refi- compact unit for the multi-stage compression of a wide range of gases. These trains are typically supplied as complete packages, including all rota-ting equipment, intercoolers and oil console. With STC-GV (S), the GV turbocompressor is also available with one single-stage spur gear resul-ting in minimized installation site work. The STC-GVT is

INGERSOLL Multi-stage compressors All the products on

Multistage Air Compressor Multi Stage High Air Pressure

In multi-stage designs, oil may be removed and the air cooled between the stages in an intercooler, or the air/oil mixture may pass through a curtain of oil as it enters the next stage. Single stage oil injected rotary screw compressor packages are available from 3 – 700 hp, or 8 – 4000 cubic feet per minute, with discharge pressures from 50 – 250 psig. Two stage versions can improve specific

two stage reciprocating air compressor diagram theory pdf 2 pump 5 hp gallon 1 phase vertical,multi stage air compressor animation the difference between a single and two 2 diagram double reciprocating,3 stage centrifugal air compressor gal two three phase electric double reciprocating diagram working,3 stage air compressor pdf multi wikipedia

the operational efficiency of an air compressor is critical. Ingersoll Rand multi-stage centrifugal compressors deliver the reliable performance our customers demand. PET Blow Molding Ingersoll Rand drives productivity within this industry by delivering advanced technology solutions that provide the lowest lifecycle cost, highest reliability and uptime, and energy efficiency. Utilities

Multiple stage reciprocating compressors are utilized to produce high pressure air. High pressure High pressure compressors are available in a number of configurations employing either a lubricated or a non-

18/10/2016 · Working principle of Multi stage reciprocating compressor.mp4.

Benefits. Our integrally geared compressors are recently redeveloped assuring an high efficiency. Our range extends from single stage air units up to API 617 state-of-the-art eight-stage CO2 compressors.

Ful-Vane™ Compressor — 100-100 from FLSmidth. The simplest compressor for the toughest jobs. Simplicity of design and operation are the keys to the success of the Ful-Vane ™ air, gas and vacuum compressor.

Discover the multi-stage compressor product range of INGERSOLL. Contact the manufacturer directly.

c) Two stage reciprocating compressor d) Multi stage reciprocating compressor 19. Which of the following parameters are not required for evaluating volumetric efficiency of the

Two Stage Air Compressor Frequency Two Stage Air

Multistage Compressor Gas Compressors and Gas Compressor

air flows through the compressor stages. 3- Surge Surge is an axisymmetrical oscillation of the flow through the compressor, and is characterized by a limit cycle in the compressor characteristic

• Single/Multi-Stage Centrifugal Compressors (API 617) • Axial Air Compressors (API 617) • Single/Multi-Stage Steam Turbines (API 611) • Multi-Stage Steam Turbines (API 612) applications • Oil Refineries • FCC Applications • Chemical/Petrochemical Plants • Ethylene Plants • Gas Lift/Gas Gathering • Gas Injection/Transport • LNG Facilities • Gas to Liquids • Ammonia

Multistage Air Compressor Final – Download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online.

Compressor Horror Stories The ‘Rod thrower’ A very dead Bauer Capitano compressor. Perhaps Something went horribly wrong with the lubrication, someone messed with the 2nd stage safety valve – or maybe it was still pumping when the dive boat sank.

free air ACFM, ICFM. Metric values are usually expressed as kg/hr, Nm 3 /hr or Im 3 /hr. Additionally, liquefied gas transfer compressors may have the capacity expressed as a liquid

c) Two stage reciprocating compressor d) Multi stage reciprocating compressor 19. Which of the following parameters are not required for evaluating volumetric efficiency of the

Benefits. Our integrally geared compressors are recently redeveloped assuring an high efficiency. Our range extends from single stage air units up to API 617 state-of-the-art eight-stage CO2 compressors.

the operational efficiency of an air compressor is critical. Ingersoll Rand multi-stage centrifugal compressors deliver the reliable performance our customers demand. PET Blow Molding Ingersoll Rand drives productivity within this industry by delivering advanced technology solutions that provide the lowest lifecycle cost, highest reliability and uptime, and energy efficiency. Utilities

In multi-stage designs, oil may be removed and the air cooled between the stages in an intercooler, or the air/oil mixture may pass through a curtain of oil as it enters the next stage. Single stage oil injected rotary screw compressor packages are available from 3 – 700 hp, or 8 – 4000 cubic feet per minute, with discharge pressures from 50 – 250 psig. Two stage versions can improve specific

multistage compressed air system using actual variable effectiveness in hot regions Shahram Azizifar and Salem Banooni Abstract In this article, modeling and optimization of power consumption of two-stage compressed air system have been investi-gated. To do so, the two-stage compressed air cycle with intercooler of Fajr Petrochemical Company was considered. This cycle includes two centrifugal

In a multi-stage operation, a first-stage compressor that sized to meet the cooling load feeds into the suction of a second-stage compressor after inter-cooling of the gas.

55528151 Multistage Air Compressor Final – Download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online.

The multi-stage gas compressor was designed to include Air Cooled Exchanger Cooling Water Pump. All Content/Information present here is the exclusive property of Rishabh Software Pvt. Ltd (RSPL). The Content/Information herein merely represents and highlights the nature of work and projects successfully undertaken by RSPL and is not intended to be advisory in nature. No representation or

two stage reciprocating air compressor diagram theory pdf 2 pump 5 hp gallon 1 phase vertical,multi stage air compressor animation the difference between a single and two 2 diagram double reciprocating,3 stage centrifugal air compressor gal two three phase electric double reciprocating diagram working,3 stage air compressor pdf multi wikipedia

Lower temperatures – Multi-stage air compressors compress the air once and then send it through an air cooling tube, which lowers the overall discharge temperatures. The lower temperatures improve the compressor’s durability and efficiency.

What are the Advantages of a Multi Stage Air Compressor

Multistage Compressor Gas Compressors and Gas Compressor

air compression, multi-stage double-acting compressors are said to be the most efficient compressors available, and are typically larger, and more costly than comparable rotary units.[6] Another type of reciprocating compressor is the swash plate compressor, which uses pistons which are moved by a swash plate mounted on a shaft – see Axial Piston Pump. Household, home …

3/09/2008 · Figure 7-9 illustrates a 4-Stage multistage centrifugal compressor system with three evaporative loads at different temperature levels, plus two stages of economizing. Figure 7-10 is the P-H diagram analysis for the 4-stage centrifugal refrigeration

• Single/Multi-Stage Centrifugal Compressors (API 617) • Axial Air Compressors (API 617) • Single/Multi-Stage Steam Turbines (API 611) • Multi-Stage Steam Turbines (API 612) applications • Oil Refineries • FCC Applications • Chemical/Petrochemical Plants • Ethylene Plants • Gas Lift/Gas Gathering • Gas Injection/Transport • LNG Facilities • Gas to Liquids • Ammonia

The multi-stage gas compressor was designed to include Air Cooled Exchanger Cooling Water Pump. All Content/Information present here is the exclusive property of Rishabh Software Pvt. Ltd (RSPL). The Content/Information herein merely represents and highlights the nature of work and projects successfully undertaken by RSPL and is not intended to be advisory in nature. No representation or

INGERSOLL Multi-stage compressors All the products on

DESIGN OPTIMIZATION OF A MULTI-STAGE AXIAL COMPRESSOR

into a throughflow code. For a full assessment of the new air-foils, these methods are applied to an existing heavy-duty gas turbine compressor test rig.

stage. 1 Air enters the compressor through the machine-mounted inlet control valve and flows to the first stage where the impeller imparts velocity energy to the air. 3 The built-in intercooler removes the heat of compression, which improves efficiency. This diagram demonstrates how a centrifugal compressor operates. The same principle applies to external cooler configurations as well. The

the operational efficiency of an air compressor is critical. Ingersoll Rand multi-stage centrifugal compressors deliver the reliable performance our customers demand. PET Blow Molding Ingersoll Rand drives productivity within this industry by delivering advanced technology solutions that provide the lowest lifecycle cost, highest reliability and uptime, and energy efficiency. Utilities

c) Two stage reciprocating compressor d) Multi stage reciprocating compressor 19. Which of the following parameters are not required for evaluating volumetric efficiency of the

PDF Flow study in centrifugal compressors is the most complicated in turbomachinery. The difficulty is mainly due to the unsymmetrical geometry of blades and volute as well as the presence of

Multistage Compressor Gas Compressors and Gas Compressor

Multi-stage gas compressor system Google Patents

air compression, multi-stage double-acting compressors are said to be the most efficient compressors available, and are typically larger, and more costly than comparable rotary units.[6] Another type of reciprocating compressor is the swash plate compressor, which uses pistons which are moved by a swash plate mounted on a shaft – see Axial Piston Pump. Household, home …

In multistage centrifugal compressors, the impeller diameter of all stages remains same, but the width of the impeller becomes progressively narrower in the …

Also, chillers with multi-stage turbo compressors are equipped with vapour admission between the compression stages. Lately, scroll compressors with connectors for additional gas admission have been entering the market, allowing the design of smaller one-compressor economizer systems. Common definitions of compressor efficiencies are insufficient to describe such compressors …

Siemens multi–stage, vertically split centrifugal barrel compressors are used in natural gas gathering, storage, gas lift and reinjection service worldwide.

Air separation, petrochemical plants & refi- compact unit for the multi-stage compression of a wide range of gases. These trains are typically supplied as complete packages, including all rota-ting equipment, intercoolers and oil console. With STC-GV (S), the GV turbocompressor is also available with one single-stage spur gear resul-ting in minimized installation site work. The STC-GVT is

The application of oil flooded screw compressors for instrument air and of dry running rotary screw compressors, sliding vane compressors and rotary lube compressors for process duties, requires the explicit approval of the Company. Rotary-type positive displacement compressors shall be in accordance with API Std. 619. Atmospheric Pressure The absolute pressure of the atmosphere at …

free air ACFM, ICFM. Metric values are usually expressed as kg/hr, Nm 3 /hr or Im 3 /hr. Additionally, liquefied gas transfer compressors may have the capacity expressed as a liquid

two stage air compressor gasket set 2 pv diagram double reciprocating lab report,3 stage air compressor 75 hp 2 pump diagram 5 horsepower cast iron industrial two,3 stage air compressor filter two theory pdf champion 2 gallon gas powered diagram,air compressor pump 2 stage 3 cylinder two for sale multi double reciprocating diagram,puma gallon

Lower temperatures – Multi-stage air compressors compress the air once and then send it through an air cooling tube, which lowers the overall discharge temperatures. The lower temperatures improve the compressor’s durability and efficiency.

Ful-Vane™ Compressor — 100-100 from FLSmidth. The simplest compressor for the toughest jobs. Simplicity of design and operation are the keys to the success of the Ful-Vane ™ air, gas and vacuum compressor.

Nowadays i making one excel sheet to calculate performance of multi-stage compressor( 2 stage, 3 stage or 4 stage) and trying to get all parameters same as available in sheet. Shared sheet is for 4 stage compressor. For this compressor i have volume of each stage with clearance, All input data like Inlet temperature, Inlet pressure, atmospheric temperature, required flow, Relative humidity

In a multi-stage operation, a first-stage compressor that sized to meet the cooling load feeds into the suction of a second-stage compressor after inter-cooling of the gas.

• Single/Multi-Stage Centrifugal Compressors (API 617) • Axial Air Compressors (API 617) • Single/Multi-Stage Steam Turbines (API 611) • Multi-Stage Steam Turbines (API 612) applications • Oil Refineries • FCC Applications • Chemical/Petrochemical Plants • Ethylene Plants • Gas Lift/Gas Gathering • Gas Injection/Transport • LNG Facilities • Gas to Liquids • Ammonia

cally controlling the air supply from a compressor group arrangement from 2 up to 15 STC-GO compressor units. With the MCP control using the highly efficient cascade

Two-Stage Full-LoadCapacity EnclosedDimensionsandWeights Motor m 3 /min acfm m/min acfm m 3 /min acfm m 3 /min acfm Length Width Height Weight Model kW hp 6.8bar @ 100psig 8.6bar @ 125psig 10.3bar @ 150psig 12bar @ 175psig mm in mm in mm in kg lb

Multistage Integrally Geared Compressors Howden

US4832578A Multi-stage compressor – Google Patents

18/10/2016 · Working principle of Multi stage reciprocating compressor.mp4.

Multistage Integrally Geared Compressors Howden

two stage air compressor gasket set 2 pv diagram double reciprocating lab report,3 stage air compressor 75 hp 2 pump diagram 5 horsepower cast iron industrial two,3 stage air compressor filter two theory pdf champion 2 gallon gas powered diagram,air compressor pump 2 stage 3 cylinder two for sale multi double reciprocating diagram,puma gallon

Advances in Mechanical Engineering 2016 Vol. 8(5) 1–10

have added to the air. If you place your hand behind the fan, you can feel movement of the air as it is being drawn into the fan. The suction is caused by a reduction in static pressure due to the acceleration of the air by the fan blades, thereby drawing more air into the fan. Now imagine that you arrange several fans in a row inside an enclosure to ensure that all of the flow goes in one

55528151 Multistage Air Compressor Final scribd.com

Two Stage Air Compressor Gallon 2 Stage Air Compressor

Benefits. Our integrally geared compressors are recently redeveloped assuring an high efficiency. Our range extends from single stage air units up to API 617 state-of-the-art eight-stage CO2 compressors.

US4832578A Multi-stage compressor – Google Patents

Multi-Stage Centrifugal Compressors Turbofluid

Air-flow in Multi-stage Centrifugal Compressor ResearchGate

• Define and calculate the interstage pressures for multiple compressors. • Define polytropic efficiency. Let’s start by considering the general use of compressed air.

INGERSOLL Multi-stage compressors All the products on

DESIGN OPTIMIZATION OF A MULTI-STAGE AXIAL COMPRESSOR